Clcik for more.

Behind the additions that are currently being made to Plant Leipzig, both on the premises and off, is e-component production. Measures will safeguard existing jobs and increase the number of new ones. At the moment more than 800 employees work in e-component production in Leipzig – projected at more than 1000 by 2024. Further jobs will be created with service providers, BMW said.

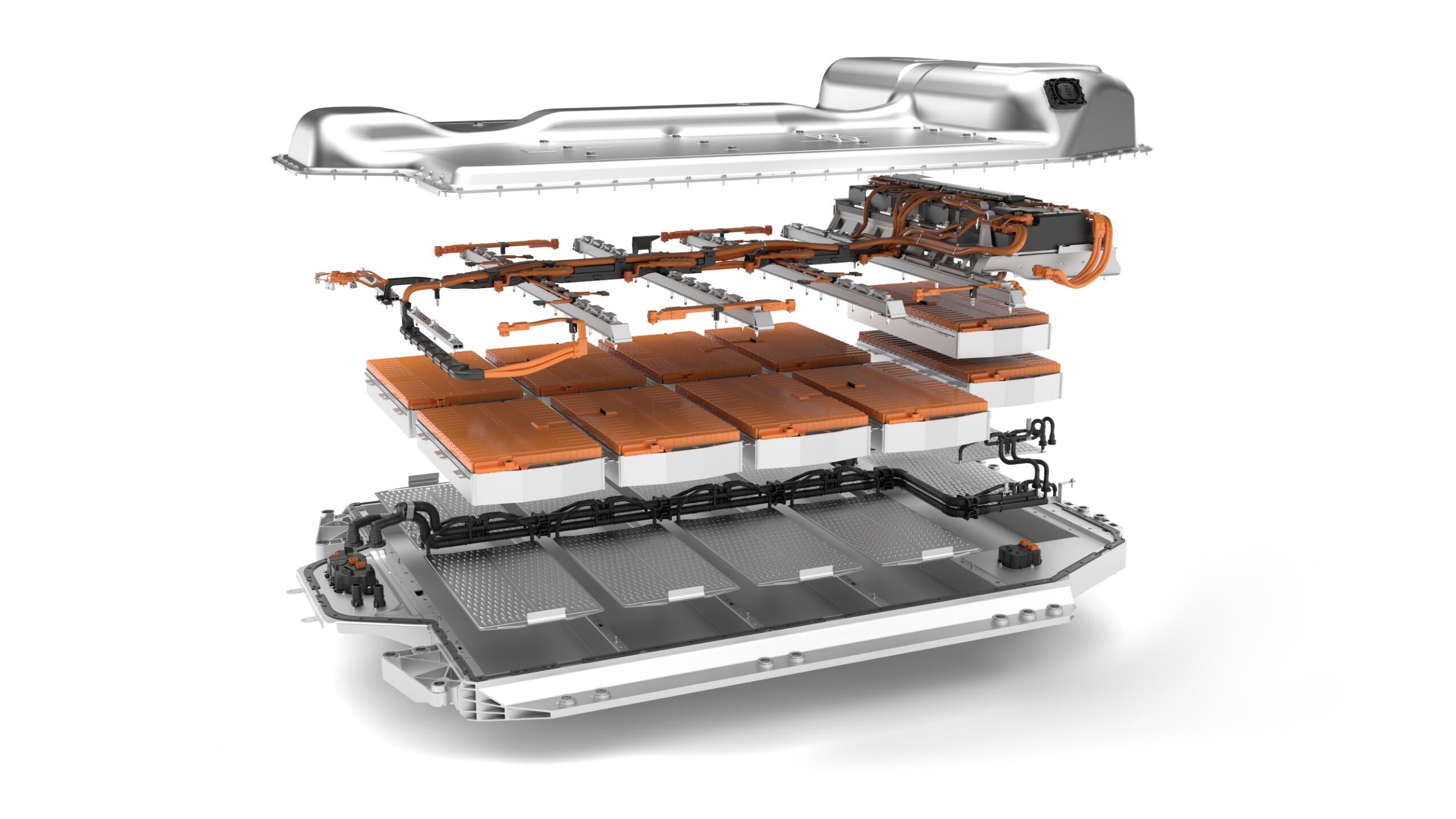

During 2024 BMW Plant Leipzig will run all three stages of the high-voltage battery production process: cell coating, module production and high-voltage battery assembly. E-component production capacity has been steadily increasing since 2021, and at present battery cells are coated and assembled into modules there. One in three battery modules for BMW Group fully electric vehicles already comes from Leipzig today. A battery assembly system is currently under construction, expected to go online early next year. The BMW Group said it is investing up to €1 billion euros in extending e-component production at Leipzig.

BMW i3 production is now phased out. Plant Leipzig will launch its next fully electric model, the new MINI Countryman during 2024. The crossover will come with a choice of combustion engines or a fully electric drive with the high-voltage batteries being made in Plant Leipzig’s workshops.