Click for more.

This is all part of the so-called BMW iFACTORY, a program to develop production methods of the of the future. During the trial run, the BMW Group said it gained valuable knowledge of what requirements must be met in order to be able to integrate so-called multi-purpose robots in an existing production system. This includes how humanoid robots communicate with the system under real conditions. After the first use in automobile production, the experts at the BMW Group and Figure are collaborating to prepare Figure for future applications in production and continuing to develop the robots, based on the findings.

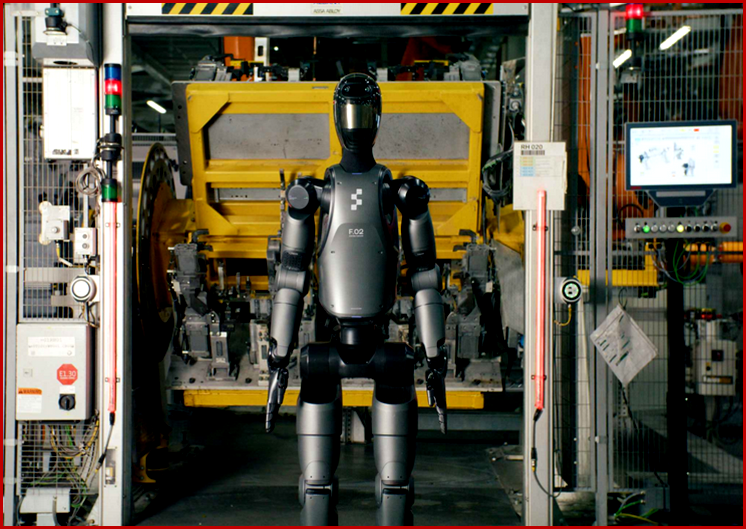

“We are excited to unveil Figure 02, our second-generation humanoid robot, which recently completed successful testing at the BMW Group Plant Spartanburg. Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously,” says Brett Adcock, Founder and CEO of Figure

Figure 02 is claimed to be the world’s most advanced humanoid robot currently available on the market. The combination of two-legged mobility and advanced dexterity means that the Figure 02 is ideally suited for use in areas with physically demanding, unsafe, or repetitive processes, thereby improving ergonomics and safety for associates. Figure02 has three times the processing power of its predecessor 01, improved voice communication, better cameras, microphones, and sensors, a high-performance battery, and fourth-generation human-scale hands with 16-degrees of freedom per hand and human-equivalent strength.

The robot is said to be capable of fully autonomous execution of human-like and two-handed tasks requiring varied and dynamic manipulation, complex grasping, and coordination of both hands in unison. It is able place various complex parts with accuracy measured in millimeters and can walk dynamically leveraging efficiencies of the robot’s design.