Since plants absorb CO2 from the atmosphere biosynthetic rubber achieves about an 20% reduction in material lifecycle carbon emissions when compared to petroleum-based hydrin rubber.

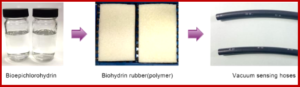

Toyota will become the world’s first automaker to use biohydrin next month, a newly-developed biosynthetic rubber, in engine and drive system hoses. Jointly developed by Toyota, Zeon Corp., and Sumitomo Riko Co., biohydrin rubber is manufactured using plant-derived bio-materials instead of epichlorohydrin, a commonly-used epoxy compound.

Since plants absorb CO2 from the atmosphere during their lifespan, biosynthetic rubber achieves an estimated 20% reduction in material lifecycle carbon emissions when compared to petroleum-based hydrin rubber.

Production of biohydrin rubber, according to Toyota, uses a variety of compound technologies for bonding plant-derived materials with petroleum-derived materials at the molecular level. These technologies ensure that biohydrin rubber provides the levels of oil resistance, heat resistance, and durability required for vacuum sensing hoses in engines and drive systems.

Biohydrin rubber is similar to conventional petroleum-based hydrin rubber in terms of quality and mass producibility, says Toyota, enabling large-scale use of biosynthetic rubber in commercial vehicles. In the future, Toyota plans to expand the usage of biohydrin to other high-performance rubber components, such as brake hoses and fuel line hoses.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.