Click for more.

*CO2e benefits achievable after only one year of use

The extensive decarbonization measures in the supply chain results in an early break-even point: when charged with electricity from the European energy mix, the CO2e footprint of the new BMW iX3 50 xDrive is lower than that of a comparable model with a combustion engine after about 21,500 kilometers (WLTP combined). When charged exclusively with electricity from renewable sources, the BMW iX3 50 xDrive beats the comparable ICE [internal combustion engine] model after 17,500 kilometers (WLTP combined), allowing customers to potentially achieve CO2e benefits in as little as one year.

De-carbonization in the Supply Chain

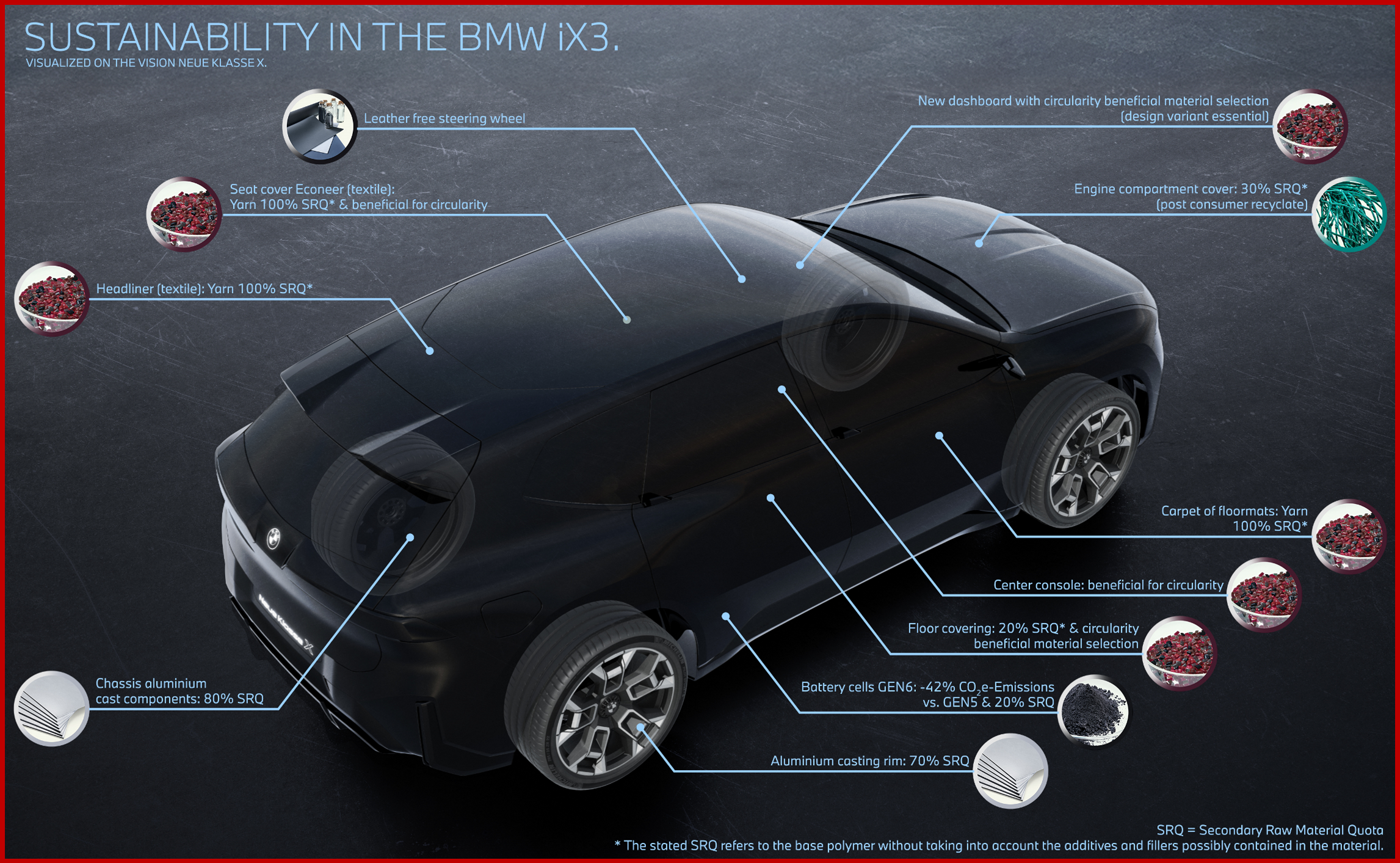

The key levers to reduce CO2eemissions in the supply chain are the use of secondary materials and renewable energy, alongside product and process innovations. This combination of measures has led to a decrease of CO2 emissions in the supply chain of 35% during product development.

The Gen6 battery cells of the BMW iX3 high-voltage storage system are made of 50% secondary cobalt, lithium, and nickel materials. In addition, renewable energies are harnessed in the anode and cathode materials and cell production. This is how CO2e emissions per watt hour were reduced by 42% compared to the Gen5 cell of the previous model.

“The BMW Group is increasingly focused on the use of innovative and secondary materials in other components as well. For instance, 30% of the secondary raw material used for the engine compartment cover and the storage compartment under the front hatch is recycled maritime plastic. This post-consumer material consists of old fishing nets and ropes, preventing these materials from potentially being dumped in the ocean. Secondary aluminum accounts for 80% of the wheel carriers and swivel bearings as well as 70% of the cast aluminum wheels,” BMW said.

BMW Group’s Debrecen plant

Designed and built according to the BMW iFactory principles, the new BMW Group plant in Debrecen, Hungary, is fully focused on efficiency, digitalization, and sustainability. It is the first BMW Group car factory that is operated and produces vehicles without using fossil fuels, such as oil and gas, under normal operating conditions.

The only energy source to power operations at the site is electricity. According to current planning, up to 25% of the plant’s annual electricity needs can be covered by the photovoltaic system located on the premises. The remaining electricity is obtained from other renewable energy sources. Surplus solar energy is stored in a heat storage unit and used to heat the paint shop ovens as needed. Only 0.1 tons of CO2 emissions are emitted in the production of a BMW iX3 car, about two-thirds below production at other BMW Group plants.

**BMW Group Sustainability Targets

The BMW Group’s commitment to the Paris Climate Agreement and to achieving Net Zero by 2050 or earlier is an integral part of the comprehensive 360° sustainability approach incorporated in the corporate strategy. The company is pursuing ambitious, scientifically derived CO2etargets for the coming years. For instance, the BMW Group intends to reduce its CO2e emissions by at least 40 million tons in 2030 (baseline: 2019).

Publicly accessible, TÜV-verified Product Carbon Footprint

For years, the BMW Group has released its vehicle footprint, which includes a greenhouse gas report for its vehicles verified by Germany’s TÜV Technical Inspection Association. The report for the new BMW iX3 50 xDRIVE is available in the My BMW app. It offers increased transparency regarding raw materials used and CO2 emissions over the entire vehicle lifecycle.