The more the U.S. market recovers, the worse it will become for automakers without capacity.

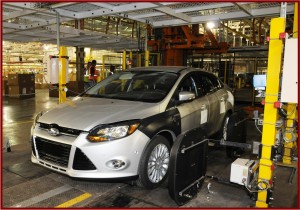

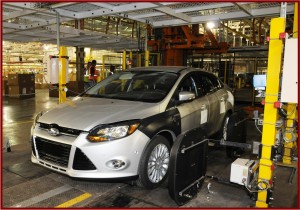

Ford Motor Company will produce about 40,000 additional vehicles this summer by idling 13 plants, including six assembly plants, for just one week instead of the traditional two, the U.S.’s Number Two Automaker said today.

It looks like Ford will lose market share this year as the market grows because Ford is already running its North American plants at maximum capacity, and it has two high volume model changes in process – its best selling Ford Fusion and Lincoln MKZ mid-size models, which go on sale as 2013 models later this year. The cancellation of the Crown Victoria, Lincoln Town Car and Ranger pickup truck adds to the capacity problem.

Ford Motor’s U.S. sales decreased 5% in April to 179,660 vehicles in a market that was up 2.3%, in part because its plants were running flat out. Ford is now facing a strong challenge from Number Three Toyota Motor Sales, which reported April sales of 178,044, up 12% y-o-y. Year-to-date, Toyota Motor trails Ford Motor by 52,000 cars and light trucks, a gap that decreases each month.

“Requiring more capacity from our plants is a good problem to have and having the flexibility to add a week of production in our plants goes a long way toward solving it,” said Jim Tetreault, vice president of North America Manufacturing.

The Ford assembly plants taking just one week of summer shutdown in 2012 include Chicago Assembly, Dearborn Truck, Kentucky Truck, Louisville Assembly, Michigan Assembly and Kansas City Assembly. Other plants taking just one week of shutdown include Dearborn Engine, Chicago Stamping, Cleveland Engine No. 1, Lima Engine, Essex Engine, Sterling and Rawsonville.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.