On the Acura LX, in place of conventional spot welding to join the panels, Honda developed a series of techniques to assemble the door, including crimping and gluing.

When the Acura RLX goes on sale in the U.S. next month, its outer door panels will be made of aluminum joined to an inner steel frame. This unusual combination of dissimilar materials results in a reduction of door panel weight by approximately 17% compared to the conventional all-steel door panel.

In addition, Honda claims that the weight reduction at the outer side of the vehicle body enables it to concentrate the center of gravity toward the middle of the vehicle, contributing to improved stability in vehicle maneuvering. This seems a marketing babble stretch, as it will be undetectable to the average driver of a street machine.

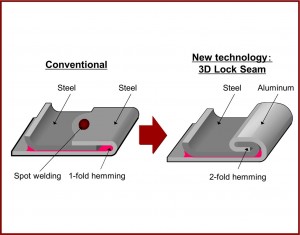

On the RLX, in place of conventional spot welding to join the panels, Honda developed a series of techniques to assemble the door. Moreover, these technologies do not require a dedicated process; as a result, the existing production line is used.

Honda, like all automakers, is frantically striving to reduce weight and increase efficiency of its vehicles.

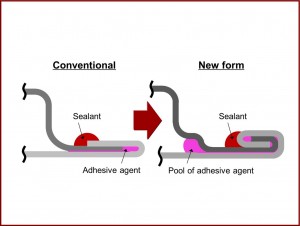

Honda uses a “3D Lock Seam” structure, whereby the steel panel and aluminum panel are layered and hemmed together twice. In order to prevent electrical corrosion caused by the dissimilar materials, Honda says it uses an anticorrosive steel for the inner panel and a new form that assures the complete filling of the gap with an adhesive. The adhesive also resists thermal deformation and holds the seam together as designed.

Honda, like all automakers (DOT and EPA Issue Record 54.5 MPG Fuel Economy Standards), is frantically striving to reduce weight and increase efficiency of its vehicles. In 2012, with the North American version of the all-new 2013 Accord, Honda began mass-production of a front sub-frame featuring the steel-aluminum hybrid structure that was made possible by the Friction Stir Welding technology.

Read AutoInformed on Honda Says New Steel and Aluminum Welding Process Cuts Weight, GM Claims Aluminum Spot Welding Innovation, First Drive: Honda’s 2013 Accord – a Comeback Car?, First Look 2014 Honda Accord Plug-In Hybrid Sedan, and Honda Claims it will lead in Fuel Economy in All Classes within Three Years. New EVs and Hybrids Coming