As the quest to lower CO2 emissions continues two engineering approaches are emerging – down size engines and run them at lower speeds. This typically results in higher stress in the engine/powertrain.

As the quest to lower CO2 emissions continues two engineering approaches are emerging – down size engines and run them at lower speeds. This typically results in higher stress in the engine/powertrain.

Engineers are looking closely at fundamental changes in combustion and parasitic losses, while monitoring material and component stresses that result.

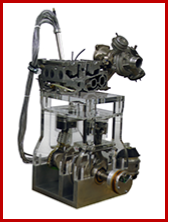

FEV, a developer of advanced powertrain and vehicle systems technology is showing a 3-cylinder technology demonstrator mock-up at the 2016 SAE World Congress, April 12-14 at Cobo Center in Detroit that highlights technologies supporting smaller, slower. Three-cylinder engines exist, of course, but more sophisticated versions are being studied to meet 2025 fuel economy rules.

FEV’s three-cylinder is quite sophisticated, with a roller bearing crankshaft with minimized bearing dimensions, a 2-stage variable compression ratio system, an integrated exhaust manifold, and active engine mounts. The 3-cylinder mock-up also has diagnostic technologies such as a triple image endoscope, optical spark plugs, and telemetric piston temperature measurement.

Triple image endoscopy can be used during the combustion development process to detect the location of pre-ignition, visualize the flame propagation, and analyze soot formation. But for a quick investigation, an optical spark plug can be used as an alternative to triple image endoscopy to help determine pre-ignition and investigate knocking locations.

FEV has also developed an innovative telemetric system to conduct detailed piston temperature assessment on running engines, utilizing wireless signal transmission. Up to 8 channels of data can be wirelessly acquired under both steady-state and transient operating conditions. Optionally, the system can be combined with analysis of piston ring dynamics using a linkage system for data transfer.