Besides rigorous real-world tests, the tool creates harsh environments.

On the darkest day of the year Nissan engineers in Michigan are still performing sunlight UV exposure tests thanks to the Xenon Weather-Ometer (XWO) tool that assesses durability in different climate conditions. Too bad it can’t be used for the State of Michigan.

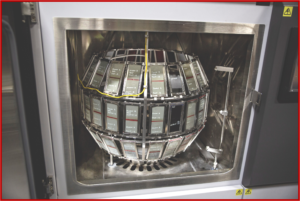

To evaluate the effects of solar energy on paint and other materials, a 4,000-watt Xenon bulb bakes 100 samples at the same wavelengths as the sun. Samples rotate around the Xenon bulb to imitate earth’s orbit – and because the “sun can shine” 24 hours a day, it takes half the time to test paint samples. The material samples endure a series of cycles to study changes and ensure top durability and quality for Nissan customers.

“In addition to rigorous real-world tests, this tool allows us to create harsh environments,” said Doug Prytula, technician, body and chassis testing, Nissan North America.

Nissan and other automakers use test environments like the XWO accelerated weather chamber to replicate conditions that occur in a natural environment. These test cells expose various types of material samples to a wide range of conditions that a vehicle may face throughout its lifecycle.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Paint Sample Testing with an Artificial Sun

Besides rigorous real-world tests, the tool creates harsh environments.

On the darkest day of the year Nissan engineers in Michigan are still performing sunlight UV exposure tests thanks to the Xenon Weather-Ometer (XWO) tool that assesses durability in different climate conditions. Too bad it can’t be used for the State of Michigan.

To evaluate the effects of solar energy on paint and other materials, a 4,000-watt Xenon bulb bakes 100 samples at the same wavelengths as the sun. Samples rotate around the Xenon bulb to imitate earth’s orbit – and because the “sun can shine” 24 hours a day, it takes half the time to test paint samples. The material samples endure a series of cycles to study changes and ensure top durability and quality for Nissan customers.

“In addition to rigorous real-world tests, this tool allows us to create harsh environments,” said Doug Prytula, technician, body and chassis testing, Nissan North America.

Nissan and other automakers use test environments like the XWO accelerated weather chamber to replicate conditions that occur in a natural environment. These test cells expose various types of material samples to a wide range of conditions that a vehicle may face throughout its lifecycle.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.