The Federal Aviation Administration today approved Boeing’s design changes for modifications to the 787 Dreamliner battery system, leading the way for the grounded plane to return to service and allowing deliveries of new aircraft to resume. The agency claimed that this would address risks at the battery cell level, the battery itself and the aircraft electronic systems.

“A team of FAA certification specialists observed rigorous tests we required Boeing to perform and devoted weeks to reviewing detailed analysis of the design changes to reach this decision,” claimed FAA Administrator Michael Huerta. Previously the FAA had approved the current battery system design, which conspicuously failed on at least two low-time Dreamliner aircraft.

According to an NTSB report on the investigation of a failure of one Nippon Air battery pack at Boston: “During the 787 certification process, Boeing performed a safety assessment (known as functional hazard assessment) to determine the potential hazards that various failure conditions of electrical system components could introduce to the airplane and its occupants. Boeing also determined that the probability that a battery could vent was once in every 10 million flight hours. As of January 16, 2013, the in-service 787 fleet had accumulated less than 52,000 flight hours, and during this period two events involving smoke from a melting 787 battery (the Boston Nippon Air meltdown and a second event [JAL fire] in Japan being investigated by the Japan Transport Safety Board) had occurred on two different 787 airplanes. The NTSB’s investigation into the probable cause of the 787 battery fire at Boston is continuing. The NTSB is also continuing to review the design, certification, and manufacturing processes for the 787 lithium-ion battery system.” The NTSB will hold hearings next week on the latest regulatory debacle in the U.S.

The battery system changes the FAA is now approving include a redesign of the internal battery components to minimize a short circuit within the battery pack, improved insulation of the cells and the addition of a new containment and venting system to prevent smoke caused by fires from entering the cabin. The battery failures resulted in release of flammable electrolytes, heat damage, and fire and/or smoke on two 787 airplanes. The root cause of these failures currently remain under investigation.

The latest battery system changes include a redesign of the internal battery components to minimize a short circuit within the battery pack, improved insulation of the cells and the addition of a new containment and venting system to prevent smoke caused by fires from entering the cabin.

United Airlines is currently the only U.S. airline operating the 787, with six airplanes grounded. The worldwide in-service fleet includes 50 aircraft in total that are also now grounded by various aviation regulators. Several hundred 787s are on order, turning the Dreamliner into a multi-billion dollar nightmare for Boeing if the planes remain hanger queens much longer.

In a brief Friday afternoon statement apparently designed to minimize coverage, the FAA said that next week it will issue instructions to operators for making changes to the aircraft and it would publish in the Federal Register the final directive that will allow the 787 to return to service with the battery system modifications. Unaddressed was the problem with the previous FAA certification that resulted in the failures.

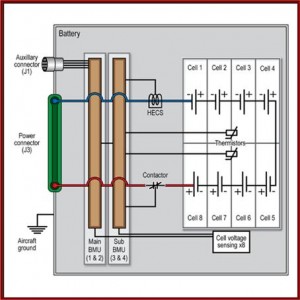

There are eight individual battery cells in the case. It also contains two circuit boards that comprise the battery-monitoring unit, a Hall Effect current sensor for monitoring, a contactor, and bus bars for the main current pathways between the cells and to the J3 connector. The J3 connector leads outside of the battery case. There are sense wires leading to the BMU and the J1 connector, which also leads outside of the battery case.

The FAA directive, much to relief of Boeing and its lobbyists, will take effect upon publication. The FAA will require airlines that operate the 787 to install containment and venting systems for the main and auxiliary system batteries, and to replace the batteries and their chargers with modified components.

It remains to be seen how foreign carriers under different regulations will be affected. As the certifying authority, the FAA said it would “continue to support other authorities around the world as they finalize their own acceptance procedures.”

The National Transportation Safety Board is also investigating the 787’s electrical system design and the FAA’s role in its initial certification. The NTSB is often critical of the FAA, which has dual roles of both promoting air commerce and regulating it for safety, for allowing unsafe operating conditions, lax regulations of pilots and mechanics or faulty designs. (See preliminary NTSB Report)

A series of mishaps on the Boeing 787 including, engine oil leaks, cracked windshields and a fire on the ramp at Boston’s Logan airport prompted the FAA to promise a “comprehensive review” of the design, manufacture and assembly of the so-called Dreamliner last January.Then a fire in Japan caused Japanese regulators to ground the plane. A reluctant FAA had no choice but to follow.

The 787 designation was the date of an elaborate unveiling during July of 2007, with the first flights planned for that August. The twin-engine composite aircraft had several production delays before finally entering service years late.

“These changes to the 787 battery will ensure the safety of the aircraft and its passengers,” said Transportation Secretary Ray LaHood, who previously maintained the 787 was safe, and only grounded them after several troubling failures the FAA was unaware of as it was subsequently revealed.

Read AutoInformed on FAA to Review Boeing 787 Design and Production; FAA Finally Grounds Boeing 787. Reluctant Regulator Acts after Two Fires. De Havilland Comet like Tragedy Avoided – for the Moment; and FAA Approves Boeing Certification Plan. 787 Still Grounded