Toyota Motor Corporation says it has a new type of airless paint atomizer that uses static electricity instead of air to replace the conventional air atomizers used in the vehicle body painting process.

Toyota Motor Corporation says it has a new type of airless paint atomizer that uses static electricity instead of air to replace the conventional air atomizers used in the vehicle body painting process.

The newly developed airless painter, said to be the first of its kind in the world, achieves more than 95% coating efficiency (the amount of paint sprayed versus the amount that actually adheres onto the vehicle body compared to conventional efficiency of approximately 60-70%.)

By deploying the airless atomizer in Toyota Group’s painting process, it is expected that the Group can reduce its CO2 emissions by about 7%. In addition, the collection device located at the bottom of the paint booth can be made more compact. Therefore, it is able to make painting production lines more compact.

By deploying the airless atomizer in Toyota Group’s painting process, it is expected that the Group can reduce its CO2 emissions by about 7%. In addition, the collection device located at the bottom of the paint booth can be made more compact. Therefore, it is able to make painting production lines more compact.

Toyota is advancing initiatives to achieve its Plant Zero CO2 Emissions Challenge, one of the targets included in the Toyota Environmental Challenge 2050 announced in 2015. As part of this effort, it developed the airless paint atomizer and deployed it at both the Takaoka and Tsutsumi Plants. Gradual deployment at other plants is planned, as well as consideration of deployment among other Toyota Group companies and licensing the technology to other companies.

Airless Paint Atomizer

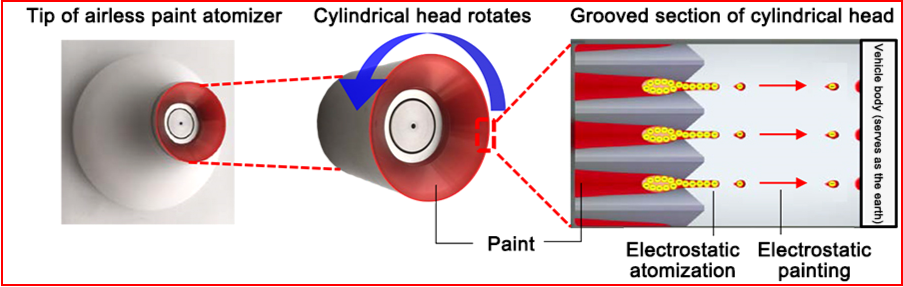

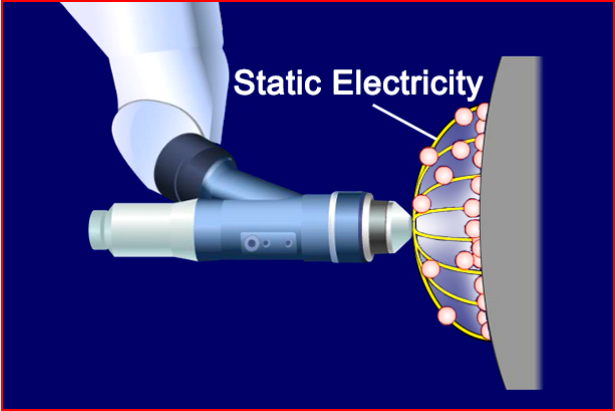

Conventional air paint atomizer sprayed paint primarily using aerodynamic force, then paint the vehicle body with the atomized particles using an air paint atomizer. For this reason, paint particles are scattered by the air bouncing off the vehicle body, resulting in a coating efficiency of approximately 60 to 70%. By comparison, the new airless paint atomizer uses electricity to spray the paint (electrostatic atomization), and the statically charged particles gravitate toward the vehicle body (electrostatic painting). Electrostatic atomization and electrostatic painting technologies greatly reduce the number of atomized particles that scatter, thereby achieving a higher coating efficiency.

Conventional air paint atomizer sprayed paint primarily using aerodynamic force, then paint the vehicle body with the atomized particles using an air paint atomizer. For this reason, paint particles are scattered by the air bouncing off the vehicle body, resulting in a coating efficiency of approximately 60 to 70%. By comparison, the new airless paint atomizer uses electricity to spray the paint (electrostatic atomization), and the statically charged particles gravitate toward the vehicle body (electrostatic painting). Electrostatic atomization and electrostatic painting technologies greatly reduce the number of atomized particles that scatter, thereby achieving a higher coating efficiency.

New Technologies That Achieve High Coating Efficiency

1.The tip of the airless paint atomizer features a rotating cylindrical head that optimize the amount of paint sprayed

Electrostatic atomization technology is used in beauty treatment devices and other instruments that spray fine amounts of liquid; here, we applied it to vehicle body painting. Specifically, the tip of the paint sprayer is cylindrical. Approximately 600 special grooves are inserted into the tip, which is rotated to create a centrifugal force, inducing the paint to flow into the grooves and atomize through static electricity. In this way, we developed the world’s first technology that paints vehicle bodies with atomized paint particles using static electricity.

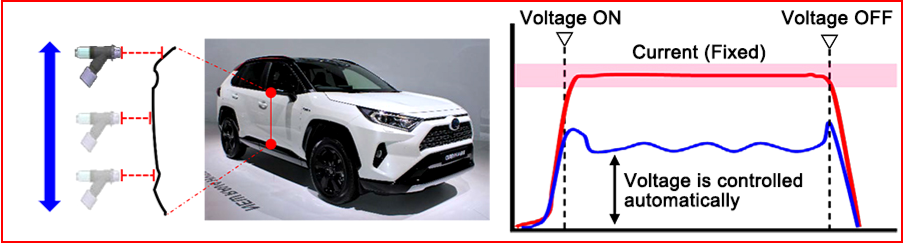

- Highly accurate current control that makes close-range painting possible

The unevenness of the vehicle body causes the distance between the cylindrical head and the vehicle body to fluctuate, making the electrical current unstable. However, the airless paint atomizer constantly monitors the variations in current and automatically controls the voltage, maintaining a distance of approximately 10 centimeters between the cylindrical head and the vehicle body. Hence, electrostatic atomization and electrostatic painting under a fixed current is rendered possible, in turn preventing variation in the size of the paint particles―the result is high-quality painting.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Toyota: New Paint Atomizer with 95% Coating Efficiency

The newly developed airless painter, said to be the first of its kind in the world, achieves more than 95% coating efficiency (the amount of paint sprayed versus the amount that actually adheres onto the vehicle body compared to conventional efficiency of approximately 60-70%.)

Toyota is advancing initiatives to achieve its Plant Zero CO2 Emissions Challenge, one of the targets included in the Toyota Environmental Challenge 2050 announced in 2015. As part of this effort, it developed the airless paint atomizer and deployed it at both the Takaoka and Tsutsumi Plants. Gradual deployment at other plants is planned, as well as consideration of deployment among other Toyota Group companies and licensing the technology to other companies.

Airless Paint Atomizer

New Technologies That Achieve High Coating Efficiency

1.The tip of the airless paint atomizer features a rotating cylindrical head that optimize the amount of paint sprayed

Electrostatic atomization technology is used in beauty treatment devices and other instruments that spray fine amounts of liquid; here, we applied it to vehicle body painting. Specifically, the tip of the paint sprayer is cylindrical. Approximately 600 special grooves are inserted into the tip, which is rotated to create a centrifugal force, inducing the paint to flow into the grooves and atomize through static electricity. In this way, we developed the world’s first technology that paints vehicle bodies with atomized paint particles using static electricity.

The unevenness of the vehicle body causes the distance between the cylindrical head and the vehicle body to fluctuate, making the electrical current unstable. However, the airless paint atomizer constantly monitors the variations in current and automatically controls the voltage, maintaining a distance of approximately 10 centimeters between the cylindrical head and the vehicle body. Hence, electrostatic atomization and electrostatic painting under a fixed current is rendered possible, in turn preventing variation in the size of the paint particles―the result is high-quality painting.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.