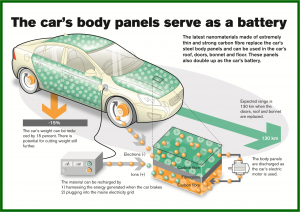

A composite blend of carbon fibers and polymer resin in experiments can store and charge more energy faster than conventional batteries can.

Volvo Car says it has developed a new lightweight battery that is molded to fit around a car’s door panels, trunk lid and wheel housing. Aside from substantially saving on space, the Chinese-owned automaker claims that reduces the heavy weight, large size and high costs associated with the batteries used in hybrids and electric vehicles today, while maintaining power and performance.

The potential battery breakthrough is made possible from the use of a combination of carbon fibers and a polymer resin, creating an advanced nano-material, and structural super capacitors.

The carbon fiber laminate is first layered, shaped and then cured in an oven to set and harden. The super capacitors are integrated within the component skin. This material is then be used around the vehicle, replacing existing components, to store and charge energy. The material is charged by the use of brake energy regeneration in the car or by plugging into an electrical grid. It then transfers the energy to the electric motor, which is discharged as it is used around the car.

The research project was funded as part of a European Union program that included Imperial College London as the academic lead partner along with eight other participants. Volvo was the only automaker in the project that took place over 3.5 years. The result are combination battery and car panels used in a Volvo S80 experimental car. Two pieces are currently under testing – the trunk lid and a plenum cover.

The boot lid is a functioning electrically powered storage component, which Volvo claims the potential to replace the standard batteries seen in today’s cars. It is lighter than a standard boot lid, saving on both volume and weight. The new plenum demonstrates that it can also replace both the front stabilizer bar, a strong structural piece, and the start-stop battery. This saves more than 50% in weight and is powerful enough to supply energy to the car’s 12-volt system. Volvo claims that the complete substitution of an electric car’s existing components with the new material could cut the overall weight by more than 15%.