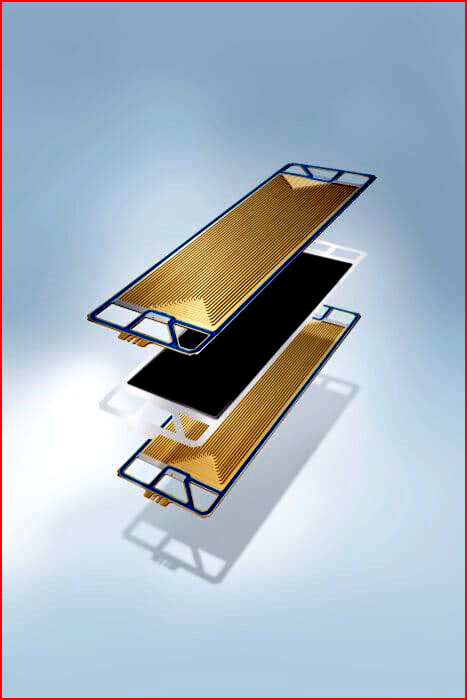

A PEM fuel cell is structured like a sandwich. In the center is a thin plastic film, the Proton Exchange Membrane (PEM). This is coated on both sides with a catalyst layer and a gas permeable electrode of graphite paper. The membrane is surrounded by two bipolar plates with milled gas ducts. Through these ducts flows hydrogen one side, and oxygen on the other. Several individual fuel cells are stacked to produce CO2 free energy.

Daimler Truck and Rolls-Royce plan to unite on the development of stationary fuel-cell generators as CO2-neutral emergency power generators for safety-critical facilities such as data centers.

They will offer emission-free alternatives to diesel engines, which are currently used as emergency power generators , or to cover peak loads. They have signed an preliminary agreement, with a comprehensive agreement due and signed by the end of the year.

In April, Daimler Truck and the Volvo Group signed a preliminary, non-binding agreement to establish a new joint venture for the development, production, and sale of fuel-cell systems for heavy-duty commercial vehicles and other uses. The Rolls-Royce Power Systems business unit plans to rely on these fuel-cell systems from the planned joint venture – as well as Daimler’s experience in the emergency power generators it develops and distributes for data centers under the MTU product and solution brand.

Daimler and Rolls-Royce are linked not only by longstanding cooperation on conventional drive systems for other applications. At the end of last year, Rolls-Royce Power Systems and Lab1886, Daimler’s innovation unit for new business models, agreed on a pilot project to develop a demonstrator for the use of this technology for stationary power supply on the basis of fuel-cell modules from the automotive sector. It will go into operation in Friedrichshafen Mercedes plant by the end of 2020.

“For Daimler Truck, fuel-cell systems play a decisive role in achieving CO2-neutral transport – as a supplement to battery-electric drive. In April, we announced our intention to establish a joint venture with the Volvo Group. With the agreement for stationary fuel-cell systems concluded, we are already demonstrating concrete opportunities for the commercialization of this technology through the joint venture,” said Martin Daum, Chairman of the Board of Management of Daimler Truck and Member of the Board of Management of Daimler AG.

“Under our MTU brand, we develop customized solutions, thousands of which we have already installed, for data centers’ individual, complex and growing energy needs… No other technology offers such high reliability, modular scalability and all the advantages of renewable energies without dependence on the conventional energy market… we will gain access to fuel-cell systems …s and will thus further strengthen our outstanding position in this growth market,” claimed Andreas Schell, CEO of Rolls-Royce Power Systems.

Earlier Series Production of Fuel Cells Possible

Daimler Truck AG and the Volvo Group plan to start large-scale production of heavy-duty fuel-cell commercial vehicles for demanding and heavy long-haul applications in the second half of the decade. However, the fuel-cell systems for stationary applications can be produced in series by the planned joint venture between Daimler Truck and the Volvo Group at an earlier stage, as the specific requirements for use in transport on public roads do not apply.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Rolls-Royce, Daimler Truck to Develop Stationary Fuel-Cells

A PEM fuel cell is structured like a sandwich. In the center is a thin plastic film, the Proton Exchange Membrane (PEM). This is coated on both sides with a catalyst layer and a gas permeable electrode of graphite paper. The membrane is surrounded by two bipolar plates with milled gas ducts. Through these ducts flows hydrogen one side, and oxygen on the other. Several individual fuel cells are stacked to produce CO2 free energy.

Daimler Truck and Rolls-Royce plan to unite on the development of stationary fuel-cell generators as CO2-neutral emergency power generators for safety-critical facilities such as data centers.

They will offer emission-free alternatives to diesel engines, which are currently used as emergency power generators , or to cover peak loads. They have signed an preliminary agreement, with a comprehensive agreement due and signed by the end of the year.

In April, Daimler Truck and the Volvo Group signed a preliminary, non-binding agreement to establish a new joint venture for the development, production, and sale of fuel-cell systems for heavy-duty commercial vehicles and other uses. The Rolls-Royce Power Systems business unit plans to rely on these fuel-cell systems from the planned joint venture – as well as Daimler’s experience in the emergency power generators it develops and distributes for data centers under the MTU product and solution brand.

Daimler and Rolls-Royce are linked not only by longstanding cooperation on conventional drive systems for other applications. At the end of last year, Rolls-Royce Power Systems and Lab1886, Daimler’s innovation unit for new business models, agreed on a pilot project to develop a demonstrator for the use of this technology for stationary power supply on the basis of fuel-cell modules from the automotive sector. It will go into operation in Friedrichshafen Mercedes plant by the end of 2020.

“For Daimler Truck, fuel-cell systems play a decisive role in achieving CO2-neutral transport – as a supplement to battery-electric drive. In April, we announced our intention to establish a joint venture with the Volvo Group. With the agreement for stationary fuel-cell systems concluded, we are already demonstrating concrete opportunities for the commercialization of this technology through the joint venture,” said Martin Daum, Chairman of the Board of Management of Daimler Truck and Member of the Board of Management of Daimler AG.

“Under our MTU brand, we develop customized solutions, thousands of which we have already installed, for data centers’ individual, complex and growing energy needs… No other technology offers such high reliability, modular scalability and all the advantages of renewable energies without dependence on the conventional energy market… we will gain access to fuel-cell systems …s and will thus further strengthen our outstanding position in this growth market,” claimed Andreas Schell, CEO of Rolls-Royce Power Systems.

Earlier Series Production of Fuel Cells Possible

Daimler Truck AG and the Volvo Group plan to start large-scale production of heavy-duty fuel-cell commercial vehicles for demanding and heavy long-haul applications in the second half of the decade. However, the fuel-cell systems for stationary applications can be produced in series by the planned joint venture between Daimler Truck and the Volvo Group at an earlier stage, as the specific requirements for use in transport on public roads do not apply.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.