However, use on a race track does not necessarily require the battery to function in sub-zero temperatures, nor remain stable for years over many charging cycles – goals which have yet to be achieved with this new version of lithium-ion battery cell technology.

In the unending endurance race among electrification contenders, Porsche said this morning that it is investing millions in a new company – Cellforce Group GmbH – as Porsche and joint venture partner Customcells today announced the launch of production of high-performance lithium-ion battery cells at the Weissach Development Center.

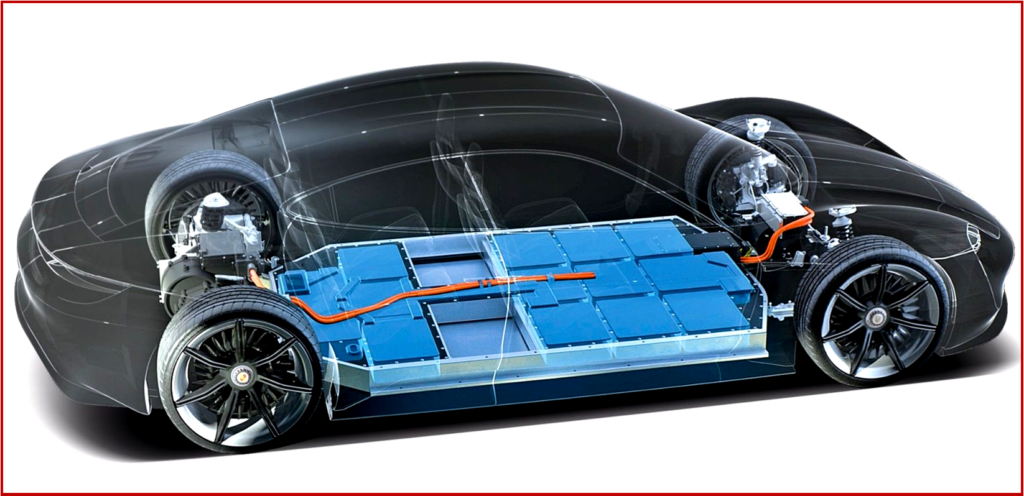

The chemistry of the new high-performance cells uses silicon as the anode material. With this material, it seems possible to significantly boost the power density compared to current batteries. The battery can offer the same energy content with a smaller size. The new chemistry reduces the battery’s internal resistance. This allows it to absorb more energy during energy recuperation and at the same time it offers improved performance for fast charging. Another special feature of the Cellforce battery cell is that it can withstand high temperatures. These are all qualities which are highly valued in motorsport.

However, use on a race track does not necessarily require the battery to function in sub-zero temperatures nor remain stable for years over many charging cycles – goals which have yet to be achieved with this new cell technology.

“The battery cell is the combustion chamber of the future. As a new Porsche subsidiary, the Cellforce Group will be instrumental in driving forward the research, development, production and sales of high-performance battery cells,” said Oliver Blume, Chairman of the Executive Board at Porsche. “This joint venture allows us to position ourselves at the forefront of global competition in developing the most powerful battery cell and make it the link between the unmistakable Porsche driving experience and sustainability. This is how we shape the future of the sports car.”

The new venture, in which Porsche has a majority stake of 83.75%, has its headquarters in Tübingen. The university town is also on the shortlist for the location of the battery factory, which is to be located in close proximity to the research and development center in Weissach, as well as the headquarters of Porsche AG in Stuttgart-Zuffenhausen. The number of employees is expected to grow from the initial workforce of 13 provided jointly by both companies to up to 80 by 2025. The Federal Republic of Germany and the state of Baden-Württemberg are funding the project with around €60 million.

“We founded Customcells with the aim of developing customer-specific battery cells for the most demanding of applications, and this is exactly what we can now realize together with Porsche. The goal for the planned production plant is to reach a minimum annual capacity of 100 MWh. This is equivalent to high performance batteries for 1,000 vehicles,” according to Torge Thönnessen, CEO of Customcells.

The chemical company BASF has been chosen as a cell development partner for the next generation of lithium-ion batteries. As a part of the collaboration, BASF is exclusively providing high-energy HEDTM NCM cathode materials for high-performance cells that enable fast charging and high energy densities. At BASF’s manufacturing facilities for primary products of cathode materials in Harjavalta, Finland, and for cathode materials in Schwarzheide, Brandenburg, Germany, BASF will be able to produce battery materials with a low carbon footprint from 2022.

The Joint Venture and Partners

The idea for a manufacturing plant for high-performance battery cells came from an initiative of the P3 Group. The Stuttgart-based management consultancy developed the concept and submitted in 2019 a funding application with Customcells as part of the European IPCEI project EuBatIn (Important Project of Common European Interest – European Battery Innovation). This aims to “build up a competitive European value chain for lithium-ion batteries, based on innovative and sustainable technologies. From the automotive industry Porsche got involved as a project partner.”

This year in 2021, P3 Group decided to “maintain neutrality and independence in the market and not to be directly involved in the joint venture. “P3 acts as a technology consultancy with a deep understanding in the field of battery cells and has concluded a long-term service contract with the Cellforce Group.

The contracts between Porsche and Customcells were signed on 21 May 2021. The Managing Directors of the new Cellforce Group GmbH are Markus Gräf as Chief Operating Officer and Wolfgang Hüsken as Chief Financial Officer from Porsche, and Torge Thönnessen as Chief Technology Officer from Customcells.

Customcells is one of the world’s leading companies in the development of special lithium-ion battery cells. At the company’s locations in Itzehoe (Schleswig-Holstein) and in Tübingen (Baden-Württemberg), Customcells develops and produces application-specific battery cells ranging from prototypes to small and medium series – Made in Germany. Since it was founded in 2012, Customcells has acquired important know-how in the field of cell development with diverse materials (cathodes, anodes, separators, electrolytes) and coating technologies. Customcells manufactures small series of special lithium-ion battery cells, for example for the aviation and shipping industries, based on agile manufacturing concepts and state-of-the-art research and production facilities.

Formally known as Dr. Ing. h.c. F. Porsche AG, aka Porsche, is a successful sports car manufacturer. The company was founded in Stuttgart in 1948 by Ferry Porsche and has been a part of the Volkswagen Group since 2012. Porsche has around 36,000 employees. In the 2020 financial year Porsche AG set a new revenue record: the value grew to €28.7 billion euros, surpassing the previous year’s figure by more than €100 million euros. It delivered more than 270,000 sports cars to customers and generated an operating profit of €4.2 billion euros. By 2030, Porsche is aiming to achieve overall carbon neutrality throughout the entire production process and life cycle of its new vehicles.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Porsche Customcells JV adds Cellforce on Manufacturing Lithium Ion Batteries as the P3 Group Leaves

However, use on a race track does not necessarily require the battery to function in sub-zero temperatures, nor remain stable for years over many charging cycles – goals which have yet to be achieved with this new version of lithium-ion battery cell technology.

In the unending endurance race among electrification contenders, Porsche said this morning that it is investing millions in a new company – Cellforce Group GmbH – as Porsche and joint venture partner Customcells today announced the launch of production of high-performance lithium-ion battery cells at the Weissach Development Center.

The chemistry of the new high-performance cells uses silicon as the anode material. With this material, it seems possible to significantly boost the power density compared to current batteries. The battery can offer the same energy content with a smaller size. The new chemistry reduces the battery’s internal resistance. This allows it to absorb more energy during energy recuperation and at the same time it offers improved performance for fast charging. Another special feature of the Cellforce battery cell is that it can withstand high temperatures. These are all qualities which are highly valued in motorsport.

However, use on a race track does not necessarily require the battery to function in sub-zero temperatures nor remain stable for years over many charging cycles – goals which have yet to be achieved with this new cell technology.

“The battery cell is the combustion chamber of the future. As a new Porsche subsidiary, the Cellforce Group will be instrumental in driving forward the research, development, production and sales of high-performance battery cells,” said Oliver Blume, Chairman of the Executive Board at Porsche. “This joint venture allows us to position ourselves at the forefront of global competition in developing the most powerful battery cell and make it the link between the unmistakable Porsche driving experience and sustainability. This is how we shape the future of the sports car.”

The new venture, in which Porsche has a majority stake of 83.75%, has its headquarters in Tübingen. The university town is also on the shortlist for the location of the battery factory, which is to be located in close proximity to the research and development center in Weissach, as well as the headquarters of Porsche AG in Stuttgart-Zuffenhausen. The number of employees is expected to grow from the initial workforce of 13 provided jointly by both companies to up to 80 by 2025. The Federal Republic of Germany and the state of Baden-Württemberg are funding the project with around €60 million.

“We founded Customcells with the aim of developing customer-specific battery cells for the most demanding of applications, and this is exactly what we can now realize together with Porsche. The goal for the planned production plant is to reach a minimum annual capacity of 100 MWh. This is equivalent to high performance batteries for 1,000 vehicles,” according to Torge Thönnessen, CEO of Customcells.

The chemical company BASF has been chosen as a cell development partner for the next generation of lithium-ion batteries. As a part of the collaboration, BASF is exclusively providing high-energy HEDTM NCM cathode materials for high-performance cells that enable fast charging and high energy densities. At BASF’s manufacturing facilities for primary products of cathode materials in Harjavalta, Finland, and for cathode materials in Schwarzheide, Brandenburg, Germany, BASF will be able to produce battery materials with a low carbon footprint from 2022.

The Joint Venture and Partners

The idea for a manufacturing plant for high-performance battery cells came from an initiative of the P3 Group. The Stuttgart-based management consultancy developed the concept and submitted in 2019 a funding application with Customcells as part of the European IPCEI project EuBatIn (Important Project of Common European Interest – European Battery Innovation). This aims to “build up a competitive European value chain for lithium-ion batteries, based on innovative and sustainable technologies. From the automotive industry Porsche got involved as a project partner.”

This year in 2021, P3 Group decided to “maintain neutrality and independence in the market and not to be directly involved in the joint venture. “P3 acts as a technology consultancy with a deep understanding in the field of battery cells and has concluded a long-term service contract with the Cellforce Group.

The contracts between Porsche and Customcells were signed on 21 May 2021. The Managing Directors of the new Cellforce Group GmbH are Markus Gräf as Chief Operating Officer and Wolfgang Hüsken as Chief Financial Officer from Porsche, and Torge Thönnessen as Chief Technology Officer from Customcells.

Customcells is one of the world’s leading companies in the development of special lithium-ion battery cells. At the company’s locations in Itzehoe (Schleswig-Holstein) and in Tübingen (Baden-Württemberg), Customcells develops and produces application-specific battery cells ranging from prototypes to small and medium series – Made in Germany. Since it was founded in 2012, Customcells has acquired important know-how in the field of cell development with diverse materials (cathodes, anodes, separators, electrolytes) and coating technologies. Customcells manufactures small series of special lithium-ion battery cells, for example for the aviation and shipping industries, based on agile manufacturing concepts and state-of-the-art research and production facilities.

Formally known as Dr. Ing. h.c. F. Porsche AG, aka Porsche, is a successful sports car manufacturer. The company was founded in Stuttgart in 1948 by Ferry Porsche and has been a part of the Volkswagen Group since 2012. Porsche has around 36,000 employees. In the 2020 financial year Porsche AG set a new revenue record: the value grew to €28.7 billion euros, surpassing the previous year’s figure by more than €100 million euros. It delivered more than 270,000 sports cars to customers and generated an operating profit of €4.2 billion euros. By 2030, Porsche is aiming to achieve overall carbon neutrality throughout the entire production process and life cycle of its new vehicles.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.