TABC today.

Toyota Motor North America (TMNA) announced today a $27 million investment in its Long Beach (aka TABC) operation to support an increase in its stamping and welding of parts for the midsize Tacoma pickup truck made in San Antonio, Texas. (AutoInformed on: Milestones – 40 Years of Toyota Auto Body – Thanks to a so-called “Chicken Tax”)

Toyota Auto Body California – commonly TABC – is now 40 years old. It was Toyota’s first manufacturing facility in the U.S. and came about because of a chicken tax. The tax was the result of a trade war between the U.S. and France and Germany, and the U.S. imposed a 25% tax on imported light trucks initially targeted at Volkswagen in 1963 because our alleged allies were blocking imports of cheap factory-farm produced American chickens with high tariffs – thus the chicken tax name.

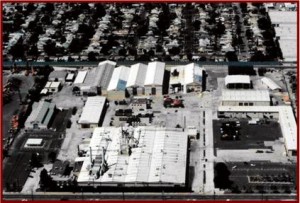

Toyota Auto Body Corporation, Long Beach, California circa 2011.

Ford Motor Company successfully lobbied the Johnson Administration to expand the tax to Japanese automakers. The simple workaround at what was then Atlas Fabricators in 1972 was to produce Toyota truck beds for pickup trucks imported into the U.S. from Japan, a strategy also used by other importers. Two years later, Toyota bought the operation and renamed it TABC, which become its first manufacturing investment in the U.S. It’s ironic that Ford, one of the Detroit Three companies that lobbied for protection against imported light trucks, later did minor stateside work on the Turkish-built Transit Connect to escape paying the chicken tax and lower the rate to 2.5% from 25%.

The investment will equip long Beach with the first coil-fed laser blanking line for TMNA, expand blanking capability to include steel and aluminum on the same line and increase capacity to cut 5.6 million blanks annually. In addition, these added capabilities will enable TABC to support Tacoma production at TMNA facilities in Baja, California, and Guanajuato, Mexico.

Currently, the facility employs more than 350 people and, with this announcement, represents a $485 million investment. Along with the new technology and expanded capabilities, the investment will also support the transition of 25 TABC variable employees to permanent positions with Toyota. Founded in 1972, TABC is Toyota’s oldest plant in North America. It also supplies service parts for multiple North American-produced Toyota vehicles.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Toyota to Upgrade Long Beach Manufacturing

TABC today.

Toyota Motor North America (TMNA) announced today a $27 million investment in its Long Beach (aka TABC) operation to support an increase in its stamping and welding of parts for the midsize Tacoma pickup truck made in San Antonio, Texas. (AutoInformed on: Milestones – 40 Years of Toyota Auto Body – Thanks to a so-called “Chicken Tax”)

Toyota Auto Body California – commonly TABC – is now 40 years old. It was Toyota’s first manufacturing facility in the U.S. and came about because of a chicken tax. The tax was the result of a trade war between the U.S. and France and Germany, and the U.S. imposed a 25% tax on imported light trucks initially targeted at Volkswagen in 1963 because our alleged allies were blocking imports of cheap factory-farm produced American chickens with high tariffs – thus the chicken tax name.

Toyota Auto Body Corporation, Long Beach, California circa 2011.

Ford Motor Company successfully lobbied the Johnson Administration to expand the tax to Japanese automakers. The simple workaround at what was then Atlas Fabricators in 1972 was to produce Toyota truck beds for pickup trucks imported into the U.S. from Japan, a strategy also used by other importers. Two years later, Toyota bought the operation and renamed it TABC, which become its first manufacturing investment in the U.S. It’s ironic that Ford, one of the Detroit Three companies that lobbied for protection against imported light trucks, later did minor stateside work on the Turkish-built Transit Connect to escape paying the chicken tax and lower the rate to 2.5% from 25%.

The investment will equip long Beach with the first coil-fed laser blanking line for TMNA, expand blanking capability to include steel and aluminum on the same line and increase capacity to cut 5.6 million blanks annually. In addition, these added capabilities will enable TABC to support Tacoma production at TMNA facilities in Baja, California, and Guanajuato, Mexico.

Currently, the facility employs more than 350 people and, with this announcement, represents a $485 million investment. Along with the new technology and expanded capabilities, the investment will also support the transition of 25 TABC variable employees to permanent positions with Toyota. Founded in 1972, TABC is Toyota’s oldest plant in North America. It also supplies service parts for multiple North American-produced Toyota vehicles.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.