Click to Enlarge.

Glencore and General Motors Co. announced today a multi-year sourcing agreement whereby Glencore will supply GM with cobalt from its Murrin Murrin (sic) operation in Australia. Cobalt is a vital metal in the production of EV batteries*. Cobalt is a metal that makes up a mere 0.001% of the earth’s crust. It is known for its heat-resistant properties and is added to lithium-ion battery cathodes to improve energy density and battery longevity.

By the end of 2025, GM plans to have capacity to build 1 million electric vehicles in North America – a doubling from earlier estimates. GM has announced actions to create a new and more secure EV supply chain, including projects targeting key EV materials and components. Cobalt processed from Australia will be used in GM’s Ultium battery cathodes, which will power electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV and Cadillac LYRIQ.

“We are delighted to announce this collaboration and support General Motors in delivering its electric vehicle strategy,” said Ash Lazenby, Glencore U.S. Cobalt marketer and trader. “Future facing commodities like cobalt play a pivotal role in decarbonizing energy consumption and the electric vehicle revolution. Glencore is already a leading producer, recycler and supplier of these commodities, which underpin our own ambition of achieving net zero total emissions by 2050.”

Both Glencore and General Motors are members of the Responsible Minerals Initiative (RMI), and Glencore’s Murrin Murrin (sic) operation is conformant with the OECD-aligned Responsible Minerals Assurance Process.

“GM and our suppliers are building an EV ecosystem that is focused on sourcing critical raw materials in a secure sustainable manner,” said Jeff Morrison, GM vice president, Global Purchasing and Supply Chain. “Importantly, given the critical role of EVs in reducing the carbon footprint of the transportation sector, this agreement is aligned with our approach to responsible sourcing and supply chain management.”

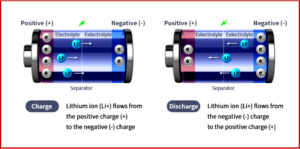

*Batteries work through an electro-chemical reaction involving lithium (Li) ions that flow back and forth from the positive pole (+) to the negative pole (-) to generate electricity. They can be recharged and reused multiple times. They are used to power mobility including EVs, IT devices and diverse home appliances. Batteries consist of four elements: cathodes, anodes, electrolytes, and separator. POSCO Chemical – another GM linked supplier – produces essential materials used in batteries — cathodes and anodes. POSCO Chemical aspires to “becoming a frontrunner in the global market by expanding production capacity, completing our value chain for raw materials, and conducting R&D in next-generation technologies as a sole producer of both cathodes and anodes in Korea based on in-depth research.”

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

EV Batteries – GM and Glencore Deal on Cobalt

Click to Enlarge.

Glencore and General Motors Co. announced today a multi-year sourcing agreement whereby Glencore will supply GM with cobalt from its Murrin Murrin (sic) operation in Australia. Cobalt is a vital metal in the production of EV batteries*. Cobalt is a metal that makes up a mere 0.001% of the earth’s crust. It is known for its heat-resistant properties and is added to lithium-ion battery cathodes to improve energy density and battery longevity.

By the end of 2025, GM plans to have capacity to build 1 million electric vehicles in North America – a doubling from earlier estimates. GM has announced actions to create a new and more secure EV supply chain, including projects targeting key EV materials and components. Cobalt processed from Australia will be used in GM’s Ultium battery cathodes, which will power electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV and Cadillac LYRIQ.

“We are delighted to announce this collaboration and support General Motors in delivering its electric vehicle strategy,” said Ash Lazenby, Glencore U.S. Cobalt marketer and trader. “Future facing commodities like cobalt play a pivotal role in decarbonizing energy consumption and the electric vehicle revolution. Glencore is already a leading producer, recycler and supplier of these commodities, which underpin our own ambition of achieving net zero total emissions by 2050.”

Both Glencore and General Motors are members of the Responsible Minerals Initiative (RMI), and Glencore’s Murrin Murrin (sic) operation is conformant with the OECD-aligned Responsible Minerals Assurance Process.

“GM and our suppliers are building an EV ecosystem that is focused on sourcing critical raw materials in a secure sustainable manner,” said Jeff Morrison, GM vice president, Global Purchasing and Supply Chain. “Importantly, given the critical role of EVs in reducing the carbon footprint of the transportation sector, this agreement is aligned with our approach to responsible sourcing and supply chain management.”

*Batteries work through an electro-chemical reaction involving lithium (Li) ions that flow back and forth from the positive pole (+) to the negative pole (-) to generate electricity. They can be recharged and reused multiple times. They are used to power mobility including EVs, IT devices and diverse home appliances. Batteries consist of four elements: cathodes, anodes, electrolytes, and separator. POSCO Chemical – another GM linked supplier – produces essential materials used in batteries — cathodes and anodes. POSCO Chemical aspires to “becoming a frontrunner in the global market by expanding production capacity, completing our value chain for raw materials, and conducting R&D in next-generation technologies as a sole producer of both cathodes and anodes in Korea based on in-depth research.”

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.