Construction begins immediately.

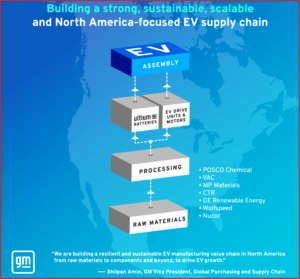

In the latest confirmation that the complicated electric vehicle transformation of the global auto business will be ruled by companies that figure out how to inexpensively make batteries, today General Motors (NYSE: GM) and POSCO Chemical* announced that they are working with the governments of Canada and Quebec to build a new facility in Bécancour, Quebec, estimated at $400 million (C$500 million).

The new plant will produce cathode active material (CAM) for GM’s Ultium batteries, which will power electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV and Cadillac LYRIQ. AutoInformed readers might remember that the companies previously announced plans to form a CAM processing joint venture in December 2021, majority owned by POSCO Chemical.

Putin’s war on Ukraine has heightened the focus on an automotive supply chain rife with totalitarian countries such as China and its EV plans, which is arguably the biggest risk to automakers operating or buying components there.

AutoInformed

Construction on the new facility, which the joint venture will operate, will begin immediately and will create approximately 200 jobs, GM said in a release. The site’s construction will allow for future expansion opportunities as GM continues to pursue many potential future EV supply chain projects.

“POSCO Chemical is set to expand battery material supplying capability across North America through establishing a cathode material plant in Canada,” said Min Kyung-Zoon, CEO of POSCO Chemical. “We will lead the successful transition to the EV era by further strengthening the strategic partnership with GM and securing a production line with world-class technological competitiveness.”

By the end of 2025, GM plans to have capacity to build 1 million electric vehicles in North America, and the company targets the majority of components by value to be sustainably sourced, processed or manufactured in North America.

*POSCO Chemical is a global advanced materials company. It is producing high-capacity Ni-rich cathode materials and low-expansion anode materials for EV batteries and has a set of technologies such as NCMA cathode, silicon anode and materials for solid-state battery. POSCO, the parent company of POSCO Chemical, is a global steel maker. POSCO Group is building a “value chain across battery business from raw materials to battery recycling.”

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

EV Battery Gold Rush – GM, POSCO Chemical JV Expansion

Construction begins immediately.

In the latest confirmation that the complicated electric vehicle transformation of the global auto business will be ruled by companies that figure out how to inexpensively make batteries, today General Motors (NYSE: GM) and POSCO Chemical* announced that they are working with the governments of Canada and Quebec to build a new facility in Bécancour, Quebec, estimated at $400 million (C$500 million).

The new plant will produce cathode active material (CAM) for GM’s Ultium batteries, which will power electric vehicles such as the Chevrolet Silverado EV, GMC HUMMER EV and Cadillac LYRIQ. AutoInformed readers might remember that the companies previously announced plans to form a CAM processing joint venture in December 2021, majority owned by POSCO Chemical.

Putin’s war on Ukraine has heightened the focus on an automotive supply chain rife with totalitarian countries such as China and its EV plans, which is arguably the biggest risk to automakers operating or buying components there.

AutoInformed

Construction on the new facility, which the joint venture will operate, will begin immediately and will create approximately 200 jobs, GM said in a release. The site’s construction will allow for future expansion opportunities as GM continues to pursue many potential future EV supply chain projects.

“POSCO Chemical is set to expand battery material supplying capability across North America through establishing a cathode material plant in Canada,” said Min Kyung-Zoon, CEO of POSCO Chemical. “We will lead the successful transition to the EV era by further strengthening the strategic partnership with GM and securing a production line with world-class technological competitiveness.”

By the end of 2025, GM plans to have capacity to build 1 million electric vehicles in North America, and the company targets the majority of components by value to be sustainably sourced, processed or manufactured in North America.

*POSCO Chemical is a global advanced materials company. It is producing high-capacity Ni-rich cathode materials and low-expansion anode materials for EV batteries and has a set of technologies such as NCMA cathode, silicon anode and materials for solid-state battery. POSCO, the parent company of POSCO Chemical, is a global steel maker. POSCO Group is building a “value chain across battery business from raw materials to battery recycling.”

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.