Click for more.

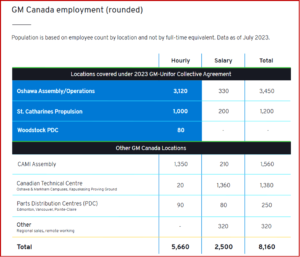

The heads of General Motors Canada and Unifor today opened 2023 collective bargaining for a new labor agreement covering ~4200 hourly workers at Oshawa Assembly Plant, St. Catharines Propulsion Plant and Woodstock Parts Distribution Center. Canada is GM’s third largest market and Unifor members are ~50% GM Canada’s total employment.

Ford and Stellantis executives are also working on new Unifor collective agreements. Confounding business as usual, for the first time since 1999 Unifor and the United Auto Workers Union (UAW) will be negotiating with the so-called Detroit Three concurrently. (AutoInformed: New Pattern Bargaining – UAW and Unifor Strike All Makers?)

In theory, the labor negotiations are separate because the UAW and what was then the Canadian Auto Workers (CAW became Unifor) split up decades ago and have bargained separately ever since. Traditionally under what’s known as pattern bargaining, the agreement that one company reaches will be replicated by the other two, with only one company targeted for a strike well after the bargaining begins.

“We look forward to working with our Unifor partners to build a competitive future that also recognizes our employees’ contributions to our shared success,” GM Canada said in a statement.

“This year, negotiations are expected to be more contentious, and UAW President Shawn Fain has alluded that things may be done differently this time around which could mean that they negotiate with all three simultaneously – ultimately leading to a strike against all of the Detroit 3 if their demands are not met,” said Taylor Prodin, Analyst, Americas Vehicle Forecasts, GlobalData.

“Given this, there could be multiple scenarios at play, but looking at the most extreme example – a strike against all three automakers – we estimate that the impact on 2023 North American production could range from a minor 1% volume impact if the UAW strikes for only 15 days, to a more severe 11% if both the UAW and Unifor strike for 100 days. Looking at 2024, we could see slightly higher production in order to make up for lost volume, although it may be contingent on vehicle demand. As in the strike of 2019, there is a risk of Mexico’s output being affected due to a lack of engines and other parts that the plants there use from the US and Canada. Other OEMs may also be affected given that some of their suppliers are UAW, although it is likely that they are working on contingency plans in the event of a strike,” according to GlobalData.

Facilities Covered Under 2023 GM-Unifor Collective Agreement per GM

Oshawa Assembly

- Chevrolet Silverado light- and heavy-duty trucks, aftermarket parts and sub-assembly

Production of the Chevrolet Silverado HD began in November 2021, and Oshawa became one of the fastest plant launches in GM history, creating 2,600 jobs. More than half of new production hires were women.

In May 2022, production of the Chevrolet Silverado 1500 began, making Oshawa the only GM facility producing both light- and heavy-duty trucks.

Truck production ramped up to three shifts in June 2022, with more than 3,100 hourly workers across the Oshawa campus.

The plant launched the refreshed 2024 Silverado HD in May and in June 2023. Part of the plant makes aftermarket parts focused on stamping, related sub-assembly and activities for GM.

GM St. Catharines Propulsion Plant

- V8 engines, HFV6 engines, dual clutch transmissions, six-speed transmissions

In 2020, GM announced plans to build dual clutch transmissions at St. Catharines Propulsion Plant.

Transmission production began in early 2022, and today St. Catharines produces powertrain components for some of GM’s highest demand products, including transmissions for Corvette, and V8 engines for full-size pickups and SUVs.

In February 2023, GM announced additional plans to retool the V6 line, subject to completing support agreements with Federal and Ontario governments, to manufacture new

Ultium electric drive units. This new project will support around 500 jobs and enable the production of more than 400,000 drive units per year for GM’s new Ultium powered EVs – such as BrightDrop, Silverado EV and Sierra EV.

Woodstock Parts Distribution Center (PDC)

- Aftermarket Replacement Parts and Accessories

Woodstock PDC opened in 1976 and the warehouse covers more than 1 million square feet. Teams onsite receive AC Delco aftermarket replacement parts and accessories from more than 1500 suppliers globally. They then send those parts to dealers and distributors across Canada and replenish stock for GM’s other Parts Distribution Centers in Vancouver, Edmonton, and Montreal.

“The pandemic and the recent supply-chain challenges highlighted the importance of these Parts Distribution Centers. Woodstock PDC operations continued to send critical repair and collision parts to dealers and vendors during a time when people were relying on their vehicles more than ever,” GM Canada said.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

General Motors Canada and Unifor Open Contract Talks

Click for more.

The heads of General Motors Canada and Unifor today opened 2023 collective bargaining for a new labor agreement covering ~4200 hourly workers at Oshawa Assembly Plant, St. Catharines Propulsion Plant and Woodstock Parts Distribution Center. Canada is GM’s third largest market and Unifor members are ~50% GM Canada’s total employment.

Ford and Stellantis executives are also working on new Unifor collective agreements. Confounding business as usual, for the first time since 1999 Unifor and the United Auto Workers Union (UAW) will be negotiating with the so-called Detroit Three concurrently. (AutoInformed: New Pattern Bargaining – UAW and Unifor Strike All Makers?)

In theory, the labor negotiations are separate because the UAW and what was then the Canadian Auto Workers (CAW became Unifor) split up decades ago and have bargained separately ever since. Traditionally under what’s known as pattern bargaining, the agreement that one company reaches will be replicated by the other two, with only one company targeted for a strike well after the bargaining begins.

“We look forward to working with our Unifor partners to build a competitive future that also recognizes our employees’ contributions to our shared success,” GM Canada said in a statement.

“This year, negotiations are expected to be more contentious, and UAW President Shawn Fain has alluded that things may be done differently this time around which could mean that they negotiate with all three simultaneously – ultimately leading to a strike against all of the Detroit 3 if their demands are not met,” said Taylor Prodin, Analyst, Americas Vehicle Forecasts, GlobalData.

“Given this, there could be multiple scenarios at play, but looking at the most extreme example – a strike against all three automakers – we estimate that the impact on 2023 North American production could range from a minor 1% volume impact if the UAW strikes for only 15 days, to a more severe 11% if both the UAW and Unifor strike for 100 days. Looking at 2024, we could see slightly higher production in order to make up for lost volume, although it may be contingent on vehicle demand. As in the strike of 2019, there is a risk of Mexico’s output being affected due to a lack of engines and other parts that the plants there use from the US and Canada. Other OEMs may also be affected given that some of their suppliers are UAW, although it is likely that they are working on contingency plans in the event of a strike,” according to GlobalData.

Facilities Covered Under 2023 GM-Unifor Collective Agreement per GM

Oshawa Assembly

Production of the Chevrolet Silverado HD began in November 2021, and Oshawa became one of the fastest plant launches in GM history, creating 2,600 jobs. More than half of new production hires were women.

In May 2022, production of the Chevrolet Silverado 1500 began, making Oshawa the only GM facility producing both light- and heavy-duty trucks.

Truck production ramped up to three shifts in June 2022, with more than 3,100 hourly workers across the Oshawa campus.

The plant launched the refreshed 2024 Silverado HD in May and in June 2023. Part of the plant makes aftermarket parts focused on stamping, related sub-assembly and activities for GM.

GM St. Catharines Propulsion Plant

In 2020, GM announced plans to build dual clutch transmissions at St. Catharines Propulsion Plant.

Transmission production began in early 2022, and today St. Catharines produces powertrain components for some of GM’s highest demand products, including transmissions for Corvette, and V8 engines for full-size pickups and SUVs.

In February 2023, GM announced additional plans to retool the V6 line, subject to completing support agreements with Federal and Ontario governments, to manufacture new

Ultium electric drive units. This new project will support around 500 jobs and enable the production of more than 400,000 drive units per year for GM’s new Ultium powered EVs – such as BrightDrop, Silverado EV and Sierra EV.

Woodstock Parts Distribution Center (PDC)

Woodstock PDC opened in 1976 and the warehouse covers more than 1 million square feet. Teams onsite receive AC Delco aftermarket replacement parts and accessories from more than 1500 suppliers globally. They then send those parts to dealers and distributors across Canada and replenish stock for GM’s other Parts Distribution Centers in Vancouver, Edmonton, and Montreal.

“The pandemic and the recent supply-chain challenges highlighted the importance of these Parts Distribution Centers. Woodstock PDC operations continued to send critical repair and collision parts to dealers and vendors during a time when people were relying on their vehicles more than ever,” GM Canada said.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.