The Rouge became a symbol of the productivity of the American worker.

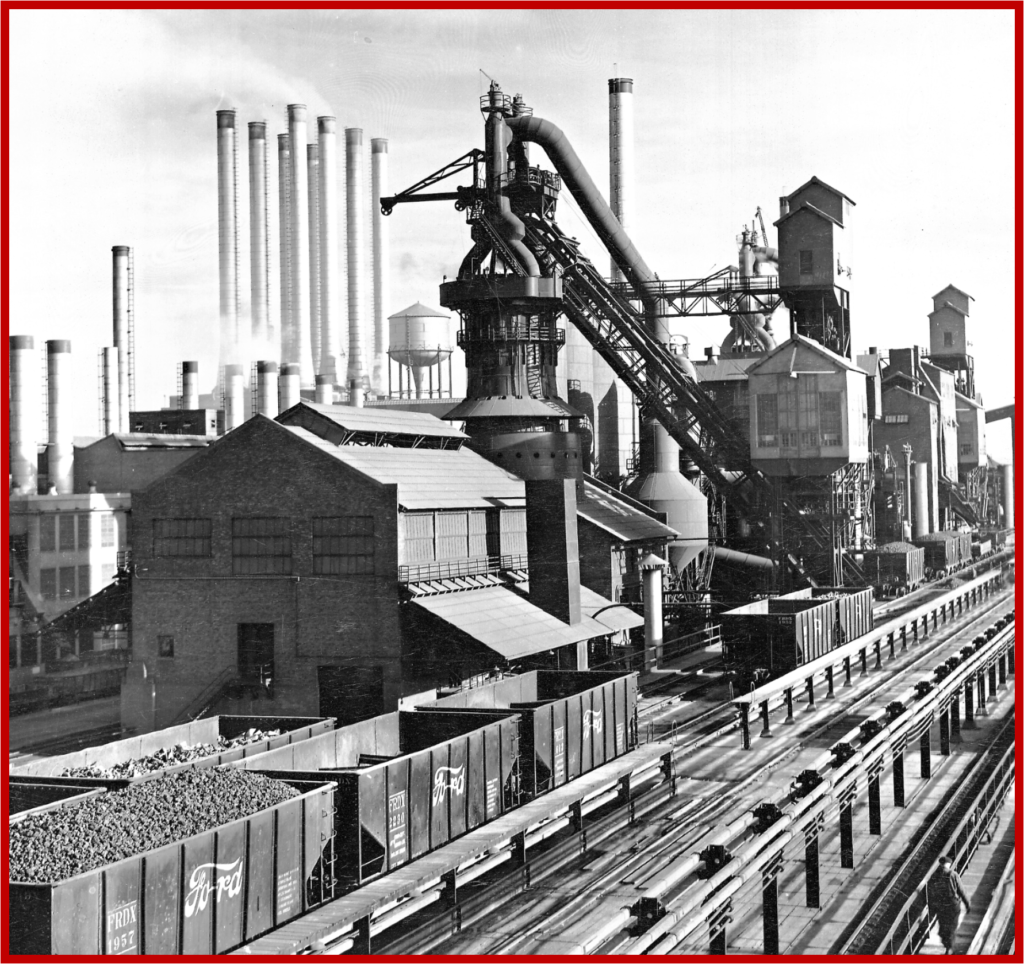

The Rouge – the first temple to the 20th Century Gods of Mass Production and Vertical Integration – is 100 years old. It is where the automotive industrial revolution took hold. Henry Ford’s vision for the facility was that it would become a fully integrated, self-sufficient manufacturing powerhouse.

By the 1930s, more than 100,000 workers punched in every day. Today, Ford employs approximately 201,000 people worldwide. and a mere 7000 at the Rouge.

By the 1930s, more than 100,000 workers punched in every day. Today, Ford employs approximately 201,000 people worldwide. and a mere 7000 at the Rouge.

If the Rouge in the early days were a city, it would have ranked as the fourth biggest in Michigan. The Rouge had its own fire department, police force, and hospital – plus a power plant, steel mill, glass factory, and hundreds of miles of rail and assembly line. Ore came into the complex, and vehicles emerged in as little as 28 hours. Today an F-series pickup is completed every 53 seconds.

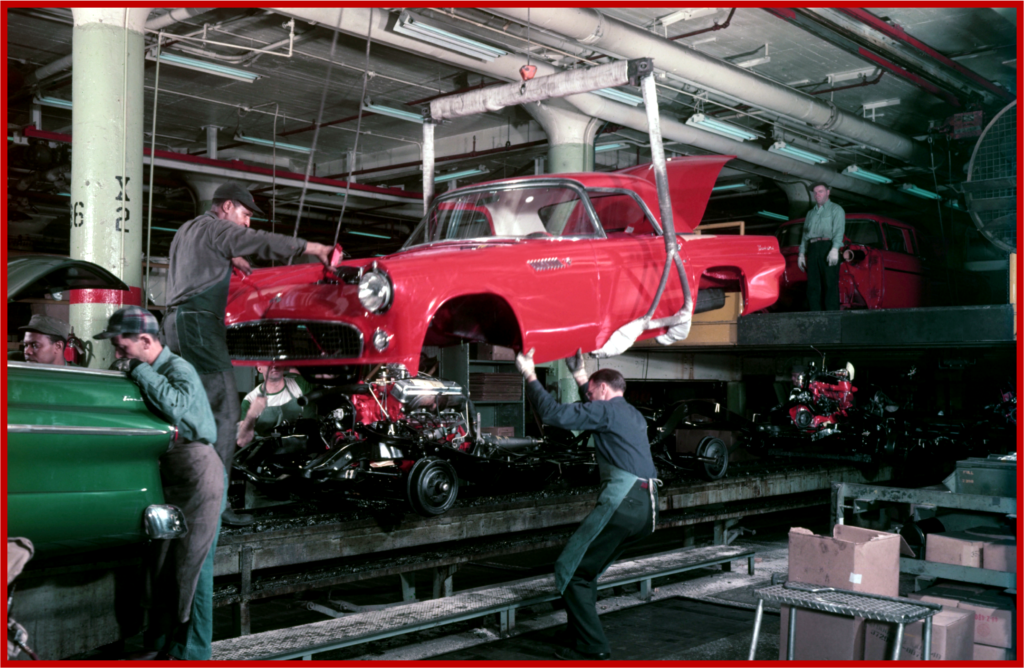

Ah, the good old 1950s: This never would have got past OSHA with the lack of hardhats, safety chains, vision protection, reflective vests?

The Rouge became a symbol of the productivity of the American worker. It’s where the $5-a-day wage took hold and helped give rise to the middle class. That is now threatened. The plant also is known for awful events that tested the resiliency of employees and the relationship between unions and companies. The Battle of the Overpass, when Walter Reuther and his union workers were beaten while for trying to organize workers, changed the thinking of people across the country, including – ultimately – Henry Ford.

Eighteen recessions over the century meant constantly rising and falling employment numbers at the Rouge. Six employees died in a power plant explosion in 1999, with more than a dozen others injured because workers tired of the false alarms of the electronic monitoring system deactivated them.

In the early 2000s senior management wanted the toxic waste riddled Rouge abandoned for a “greenfield” site. Bill Ford, the great grandson of Henry, forced the company to in effect doubled down on what was once a winning bet transforming the aging complex into a modern and sustainable manufacturing complex.

More than 10 million people have toured the Rouge. The guest list includes celebrities and political hacks, including President Bill Clinton in 2004 and Facebook founder Mark Zuckerberg, a company who in its latest assault of people’s privacy resulted in a data breach of 50 million.

“To us, it’s more than a factory,” Bill Ford said. “It’s a source of pride for generations of workers …. It’s an all-American symbol of strength, opportunity, and hope; a place where we’ve always been creating tomorrow together.”

Second Act?

As new electronic technologies disrupt the industry and threaten people’s privacy and autonomy, Ford has opened a 135,000 square foot Advanced Manufacturing Center in nearby Redford. At the same time, the UAW and Ford are expanding a training facility just a few miles from the Rouge in Allen Park so employees can “learn how to adapt to these disruptions.” The goal: Create the workforce of the 21st century.

Ford designed these facilities to accelerate the pace of manufacturing innovation in the areas of robotics, 3D printing, virtual reality and process innovation including collaborative robots, artificial intelligence and digital factories.

These core competencies aim to improve the efficiency of the facility and its 7,500 employees. During the plant’s three-crew shift cadence, a new F-150 rolls off the end of the assembly line every 53 seconds, as noted. In 2020, the plant begins producing the first F-150 Hybrid.

With the switch to aluminum for F-150 bodies in 2014, the plant added an aluminum recycling system. This closed-loop system, with two miles of duct work and computer-controlled gates, has helped Ford recycle 12 to 15 million pounds of aluminum a month at the Rouge. That’s enough to build more than 37,000 F-series truck bodies a month – equaling 144 million to 180 million pounds of aluminum per year.

The plant, which recently reached zero-waste-to-landfill status, is also part of the company’s broader water reduction strategy. Ford’s long-term goal is to use zero potable (drinking) water in its manufacturing processes. To help clean the nearby Rouge River, Ford is launching a volunteer program with Friends of the Rouge, a local NGO dedicated to cleaning up and preserving the Rouge River.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Milestones: Rouge at 100 Years

The Rouge became a symbol of the productivity of the American worker.

The Rouge – the first temple to the 20th Century Gods of Mass Production and Vertical Integration – is 100 years old. It is where the automotive industrial revolution took hold. Henry Ford’s vision for the facility was that it would become a fully integrated, self-sufficient manufacturing powerhouse.

If the Rouge in the early days were a city, it would have ranked as the fourth biggest in Michigan. The Rouge had its own fire department, police force, and hospital – plus a power plant, steel mill, glass factory, and hundreds of miles of rail and assembly line. Ore came into the complex, and vehicles emerged in as little as 28 hours. Today an F-series pickup is completed every 53 seconds.

Ah, the good old 1950s: This never would have got past OSHA with the lack of hardhats, safety chains, vision protection, reflective vests?

The Rouge became a symbol of the productivity of the American worker. It’s where the $5-a-day wage took hold and helped give rise to the middle class. That is now threatened. The plant also is known for awful events that tested the resiliency of employees and the relationship between unions and companies. The Battle of the Overpass, when Walter Reuther and his union workers were beaten while for trying to organize workers, changed the thinking of people across the country, including – ultimately – Henry Ford.

Eighteen recessions over the century meant constantly rising and falling employment numbers at the Rouge. Six employees died in a power plant explosion in 1999, with more than a dozen others injured because workers tired of the false alarms of the electronic monitoring system deactivated them.

In the early 2000s senior management wanted the toxic waste riddled Rouge abandoned for a “greenfield” site. Bill Ford, the great grandson of Henry, forced the company to in effect doubled down on what was once a winning bet transforming the aging complex into a modern and sustainable manufacturing complex.

More than 10 million people have toured the Rouge. The guest list includes celebrities and political hacks, including President Bill Clinton in 2004 and Facebook founder Mark Zuckerberg, a company who in its latest assault of people’s privacy resulted in a data breach of 50 million.

“To us, it’s more than a factory,” Bill Ford said. “It’s a source of pride for generations of workers …. It’s an all-American symbol of strength, opportunity, and hope; a place where we’ve always been creating tomorrow together.”

Second Act?

As new electronic technologies disrupt the industry and threaten people’s privacy and autonomy, Ford has opened a 135,000 square foot Advanced Manufacturing Center in nearby Redford. At the same time, the UAW and Ford are expanding a training facility just a few miles from the Rouge in Allen Park so employees can “learn how to adapt to these disruptions.” The goal: Create the workforce of the 21st century.

Ford designed these facilities to accelerate the pace of manufacturing innovation in the areas of robotics, 3D printing, virtual reality and process innovation including collaborative robots, artificial intelligence and digital factories.

These core competencies aim to improve the efficiency of the facility and its 7,500 employees. During the plant’s three-crew shift cadence, a new F-150 rolls off the end of the assembly line every 53 seconds, as noted. In 2020, the plant begins producing the first F-150 Hybrid.

With the switch to aluminum for F-150 bodies in 2014, the plant added an aluminum recycling system. This closed-loop system, with two miles of duct work and computer-controlled gates, has helped Ford recycle 12 to 15 million pounds of aluminum a month at the Rouge. That’s enough to build more than 37,000 F-series truck bodies a month – equaling 144 million to 180 million pounds of aluminum per year.

The plant, which recently reached zero-waste-to-landfill status, is also part of the company’s broader water reduction strategy. Ford’s long-term goal is to use zero potable (drinking) water in its manufacturing processes. To help clean the nearby Rouge River, Ford is launching a volunteer program with Friends of the Rouge, a local NGO dedicated to cleaning up and preserving the Rouge River.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.