Let’s hope that this catches on – not only for collectors of rare classic cars – but for older vehicle or airplane owners of whatever ilk. It is not fake news that the absence of replacement items (or, ahem, ethics) leads to problems. Worst auto case, the car may be scrapped.

Now Porsche Classic, the division of Porsche dedicated to – what else – classic vehicles, has a solution by producing extremely rare parts that are admittedly only needed in small quantities using 3D printers. All parts that are produced using the 3D printing process meet the requirements with conformity to original specifications – both from a technical and a visual perspective.

The Porsche Classic range currently includes some 52,000 parts. If a certain spare part is no longer in stock or dwindling toward extinction, it is reproduced using the original tools. For larger quantities, production may require the use of new tools. However, ensuring the supply of spare parts that are only required in very limited numbers poses a major challenge, even for the experts. Producing small batches using new tools would be largely inefficient. Before embarking on a project to produce a component, Porsche evaluates various manufacturing processes.

Quality versus Quantity

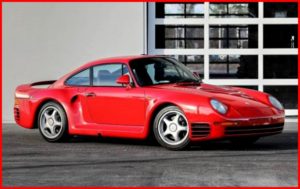

As the quality of “additive” manufacturing processes continues to improve with generally decreasing costs, this form of manufacturing presents an economic alternative to produce small quantities. In a real example about a dreamlike car, the release lever for the clutch on the Porsche 959 is no longer available. This component made from grey cast iron is subject to high quality requirements but is in very low demand – because only 292 of these sports cars were ever produced.

The only manufacturing process worth considering would be so-called “selective laser melting.” To make a new release lever, a layer of powdery tool steel less than 0.1 millimeters thick is applied to a processing plate during a computerized procedure. In an inert atmosphere, a high-energy light beam then melts the powder in the desired locations to create a steel layer. Thus, the complete three-dimensional component is produced, layer by layer. Both a pressure test with a load of almost three tons, and subsequent tomographic examination for internal faults were passed by the printed release lever. The practical tests with the lever installed in a test vehicle and “extensive driving tests confirm” the quality and function of the lever.

Due to what it claims are “consistently positive results,” Porsche is currently manufacturing eight other parts using 3D printing. The parts in question are steel and alloy parts produced using the selective laser melting process, and plastic components manufactured using an SLS printer. (SLS – selective laser sintering -, a process where the material is heated to just below melting point and the remaining energy is applied through a laser to fuse the plastic powder at a selected point.) All parts are subject to the quality requirements of the original production period as a minimum, though they usually meet higher standards says Stuttgart. Accuracy of size and fit are ensured by performing tests with the part installed. Depending on the area of application, plastic parts made of various materials as in the original must be resistant to oils, fuels, acids and light.

More Coming

Porsche Classic is currently testing whether 3D printing is suitable to produce a further 20 components. The benefits: Three-dimensional design data or a 3D scan of the component is a sufficient basis to commence production. The components can be produced on demand if needed, thereby eliminating tool and storage costs.