The greatest concentration of auto plant closings and resulting economic harm is in the traditional automotive production center, the Midwest.

The Center for Automotive Research (CAR) today released new research on making ex automotive manufacturing sites productive again. Not surprisingly, successful auto plant redevelopment occurs more frequently in desirable waterfront or urban locations in the non-union southern states or coastal states, while empty plants in the Rust Belt languish.

The study is the latest example of how devastating the collapse of the automobile industry is to the economies of local communities, many of them now with grim futures. Simply put, the best outcome for a community is to keep auto plants operating. The lack of a U.S. industrial policy – alone among all other industrialized nations and clearly a problem in the view of critics of multinational corporations – is not addressed in the study, which attempts to make informed policy recommendations about redeveloping still closed sites.

The CAR research is also a grim reminder that the loss of U.S. manufacturing jobs is not helping the ongoing unemployment crisis and budget deficit that politicians in Washington are posturing over but doing nothing about. While almost half of closed former automaker sites have new, productive uses, the jobs created are only a fraction of those lost when the plants closed, and it’s likely that total tax revenues have declined as well.

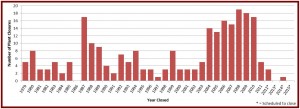

CAR said that 60% – 267 – of the 447 automaker manufacturing plants that were operating as of 1979 have closed. Of the closed plants, 48% (128) have been at least partially re-adopted or are in the process of transitioning to a new use.

In the survey conducted that is the core of the study, 45% of respondents said the new use either employs or will potentially employ 100 or more people, 17% said the new use employs or will employ 800 or more people, and 16% said employment on the site is or will be 50-99 people.

Given that more than 75% of respondents said the original manufacturing plants employed more than 400 people, new uses at the site generally offer fewer employment opportunities. Nothing was said about wages or benefits paid to the new, presumably mostly non-union workers.

Closed automotive facilities were found in 28 states, and 65% were concentrated in the Midwest states of Indiana, Michigan and Ohio. Detailed case studies were selected to reflect the population of closed facilities and included the communities of Baltimore, MD; Batavia, OH; Coopersville, MI; Doraville, GA; Kenosha, WI; Sleepy Hollow, NY; and South Gate, CA.

CAR found that what it calls “repurposing rates’ were lower in counties with high unemployment, declining population, and a high concentration of closed auto facilities, and recommends public policy initiatives be targeted toward these areas.

The work was completed with funds from the U.S. Department of Labor, Office of Recovery for Auto Communities and Workers, and is the first comprehensive list of closed automaker manufacturing facilities across the country.

“The findings will assist our office as we continue to help leaders navigate the local, state, and federal resources available to revitalize former auto communities,” said Jay Williams, Director of the Office of Recovery for Auto Communities and Workers.