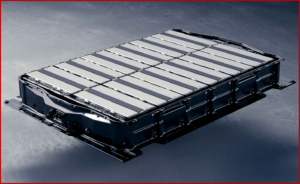

The dirty secret is that EVs really aren’t clean. Click to Enlarge.

Ultium Cells LLC, a joint venture between General Motors and LG Energy Solution, announced an agreement today with Li-Cycle to recycle up to 100% of the material scrap from battery cell manufacturing.

The new recycling process will allow Ultium Cells in theory to recycle battery materials, including cobalt, nickel, lithium, graphite, copper, manganese and aluminum. It’s estimated that 95% of these materials can be used in the production of new batteries or for other industries. The hydro-metallurgical process through which these battery materials will be recycled emits 30% less greenhouse gas than traditional processes, it’s claimed, helping to minimize environmental impact.

“Our combined efforts with Ultium Cells will be instrumental in redirecting battery manufacturing scrap from landfills and returning a substantial amount of valuable battery-grade materials back into the battery supply chain,” said Ajay Kochhar, Li-Cycle’s president and CEO and co-founder. “This partnership is a critical step forward in advancing our proven lithium-ion resource recovery technology as a more sustainable alternative to mining.”

GM’s so-called zero-waste initiative aims to divert more than 90% of its manufacturing waste from landfills and incineration globally by 2025. Mining, of course is an environmentally ruinous process with severe negative social effects. The dirty secret is that EVs really aren’t clean when manufacturing and energy generation are taken into account.

Since 2013, GM has recycled or reused 100% of the battery packs received from customers, including any packs replaced through warranty service. Most current GM EVs are repaired with refurbished packs. Ultium batteries will have a modular design, also making them easy to reuse or recycle.

AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Ultium Cells and Li-Cycle to Expand Recycling in North America

The dirty secret is that EVs really aren’t clean. Click to Enlarge.

Ultium Cells LLC, a joint venture between General Motors and LG Energy Solution, announced an agreement today with Li-Cycle to recycle up to 100% of the material scrap from battery cell manufacturing.

The new recycling process will allow Ultium Cells in theory to recycle battery materials, including cobalt, nickel, lithium, graphite, copper, manganese and aluminum. It’s estimated that 95% of these materials can be used in the production of new batteries or for other industries. The hydro-metallurgical process through which these battery materials will be recycled emits 30% less greenhouse gas than traditional processes, it’s claimed, helping to minimize environmental impact.

“Our combined efforts with Ultium Cells will be instrumental in redirecting battery manufacturing scrap from landfills and returning a substantial amount of valuable battery-grade materials back into the battery supply chain,” said Ajay Kochhar, Li-Cycle’s president and CEO and co-founder. “This partnership is a critical step forward in advancing our proven lithium-ion resource recovery technology as a more sustainable alternative to mining.”

GM’s so-called zero-waste initiative aims to divert more than 90% of its manufacturing waste from landfills and incineration globally by 2025. Mining, of course is an environmentally ruinous process with severe negative social effects. The dirty secret is that EVs really aren’t clean when manufacturing and energy generation are taken into account.

Since 2013, GM has recycled or reused 100% of the battery packs received from customers, including any packs replaced through warranty service. Most current GM EVs are repaired with refurbished packs. Ultium batteries will have a modular design, also making them easy to reuse or recycle.

AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.