Click for more information.

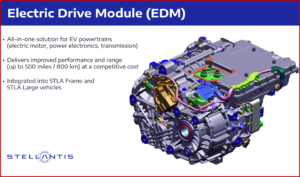

Stellantis (NYSE: STLA) announced today that it will invest a total of $155 million in three Kokomo, Indiana, plants to produce new electric drive modules (EDM) that will help power future electric vehicles assembled in North America. The money will be spent at Indiana Transmission, Kokomo Transmission and Kokomo Casting Plants. Production is expected to start in the third quarter of 2024, following retooling.

As a result more than 265 jobs will survive. Stellantis* said that its total investments in Indiana since 2020 to support electrification goals will increase to nearly $3.3 billion, including gigafactory joint venture with Samsung SDI. This is to support the goal of 50% battery electric sales in the U.S. by 2030.

“While we continue our successful transition to a decarbonized future in our European operations, we are now setting those same foundational elements for the North American market,” said Carlos Tavares, Stellantis CEO. “By combining the benefits of the EDM with our new BEV-centric platforms and innovative battery technologies, we will offer our customers a variety of electric vehicles with unparalleled performance and range at more affordable prices. And with our in-house manufacturing capabilities and expertise, we will do it with greater flexibility and efficiency.”

Investments will be made at the Indiana Transmission, Kokomo Transmission and Kokomo Casting Plants. The gearbox cover will be cast at Kokomo Casting and machined at Kokomo Transmission. Gear machining and final assembly will be at the Indiana Transmission Plant.”

As part of the Dare Forward 2030 strategic plan (AutoInformed.com: Dare Forward 2030 – Stellantis Survival Plan Unveiled), Stellantis expects to achieve a 100% passenger car battery electric vehicle (“BEV”) sales mix in Europe and a 50% passenger car and light-duty truck BEV sales mix in the United States by 2030. In Brazil, it is targeting approximately 20% low emission vehicle (“LEV”) sales mix by the end of the decade. The plan is anchored in an ambitious decarbonization strategy consistent with science-based recommendations. Through aggressive and clear targets, by 2030(1) it plans to reduce its carbon emissions footprint by half versus 2021 metrics, putting the Stellantis on track to achieve carbon net zero by 2038

AutoInformed on

Stellantis in Indiana

Stellantis currently operates five powertrain plants in Indiana – three transmission plants, a casting plant and an engine plant. The portfolio of transmissions includes six-, eight- and nine-speed transmissions, as well as the SiEVT transmission for the Chrysler Pacifica plug-in hybrid electric minivan, built at the Windsor Assembly Plant in Ontario, Canada. The casting plant produces aluminum parts for automotive components, transmission and transaxle cases, and engine block castings. The engine plant produces the GMET4 – the Company’s 2.0-liter Global Medium Engine inline four-cylinder turbo.

*Stellantis N.V. (NYSE: STLA / Euronext Milan: STLAM / Euronext Paris: STLAP) is one of the world’s larger automakers and a mobility provider. Its brands include Abarth, Alfa Romeo, Chrysler, Citroën, Dodge, DS Automobiles, Fiat, Jeep®, Lancia, Maserati, Opel, Peugeot, Ram, Vauxhall, Free2move and Leasys.

“Powered by our diversity, we lead the way the world moves – aspiring to become the greatest sustainable mobility tech company, not the biggest, while creating added value for all stakeholders as well as the communities in which it operates,” says the Stellantis mission statement.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Stellantis to Convert Three Indiana Plants to EV Components

Click for more information.

Stellantis (NYSE: STLA) announced today that it will invest a total of $155 million in three Kokomo, Indiana, plants to produce new electric drive modules (EDM) that will help power future electric vehicles assembled in North America. The money will be spent at Indiana Transmission, Kokomo Transmission and Kokomo Casting Plants. Production is expected to start in the third quarter of 2024, following retooling.

As a result more than 265 jobs will survive. Stellantis* said that its total investments in Indiana since 2020 to support electrification goals will increase to nearly $3.3 billion, including gigafactory joint venture with Samsung SDI. This is to support the goal of 50% battery electric sales in the U.S. by 2030.

“While we continue our successful transition to a decarbonized future in our European operations, we are now setting those same foundational elements for the North American market,” said Carlos Tavares, Stellantis CEO. “By combining the benefits of the EDM with our new BEV-centric platforms and innovative battery technologies, we will offer our customers a variety of electric vehicles with unparalleled performance and range at more affordable prices. And with our in-house manufacturing capabilities and expertise, we will do it with greater flexibility and efficiency.”

Investments will be made at the Indiana Transmission, Kokomo Transmission and Kokomo Casting Plants. The gearbox cover will be cast at Kokomo Casting and machined at Kokomo Transmission. Gear machining and final assembly will be at the Indiana Transmission Plant.”

As part of the Dare Forward 2030 strategic plan (AutoInformed.com: Dare Forward 2030 – Stellantis Survival Plan Unveiled), Stellantis expects to achieve a 100% passenger car battery electric vehicle (“BEV”) sales mix in Europe and a 50% passenger car and light-duty truck BEV sales mix in the United States by 2030. In Brazil, it is targeting approximately 20% low emission vehicle (“LEV”) sales mix by the end of the decade. The plan is anchored in an ambitious decarbonization strategy consistent with science-based recommendations. Through aggressive and clear targets, by 2030(1) it plans to reduce its carbon emissions footprint by half versus 2021 metrics, putting the Stellantis on track to achieve carbon net zero by 2038

AutoInformed on

Stellantis in Indiana

Stellantis currently operates five powertrain plants in Indiana – three transmission plants, a casting plant and an engine plant. The portfolio of transmissions includes six-, eight- and nine-speed transmissions, as well as the SiEVT transmission for the Chrysler Pacifica plug-in hybrid electric minivan, built at the Windsor Assembly Plant in Ontario, Canada. The casting plant produces aluminum parts for automotive components, transmission and transaxle cases, and engine block castings. The engine plant produces the GMET4 – the Company’s 2.0-liter Global Medium Engine inline four-cylinder turbo.

*Stellantis N.V. (NYSE: STLA / Euronext Milan: STLAM / Euronext Paris: STLAP) is one of the world’s larger automakers and a mobility provider. Its brands include Abarth, Alfa Romeo, Chrysler, Citroën, Dodge, DS Automobiles, Fiat, Jeep®, Lancia, Maserati, Opel, Peugeot, Ram, Vauxhall, Free2move and Leasys.

“Powered by our diversity, we lead the way the world moves – aspiring to become the greatest sustainable mobility tech company, not the biggest, while creating added value for all stakeholders as well as the communities in which it operates,” says the Stellantis mission statement.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.