Altair and the Center for Automotive Research (CAR) have announced the winners of the 6th annual Altair Enlighten Award just before lunch today at the 2018 CAR Management Briefing Seminars (MBS) in Traverse City, Michigan.

The award “honors the greatest achievements in vehicle weight savings each year.” The award purports to “ incentivizes automotive light-weighting advancements and provides a global platform to recognize and share technological achievements.

Joining GM, BMW, Asahi Kasei, Mazda, Sika Automotive, were United States Steel and American Axle & Manufacturing in the top spots. The award is judged by an independent panel of automotive industry experts, academia and the engineering media who selected 6 winners from a field of 57 finalists this year.

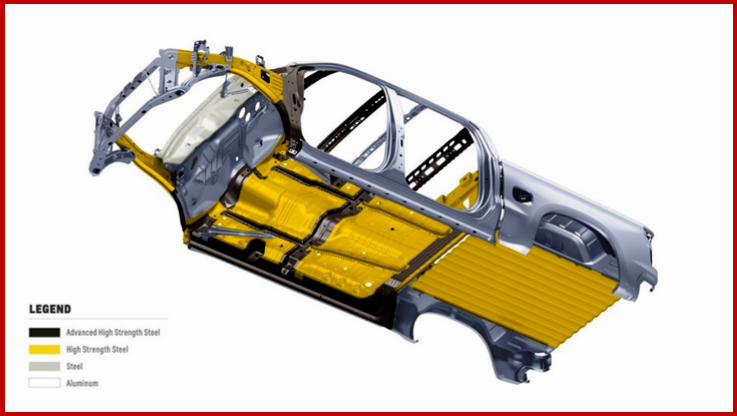

The winner in the Full Vehicle category was the behemoth General Motors’ 2019 Chevrolet Silverado, which weighed in at 450 pounds (204.5 kilograms) lighter than its 2014 predecessor. GM was caught napping when Ford introduced its aluminum intensive F-Series – long the best-selling vehicle in the U.S. (Ford F-150 Aluminum Pickup Sheds 700 Pounds Late this Year or Ford – 100 Years of Trucks – 1917 Model TT to 2017 Raptor and Significant Stories, Trends of 2017. And 2018?) Ford Motor and Alcoa then produced the next-generation automotive Micromill aluminum alloys that are more design-friendly in multiple components on the 2016 F-150, thereby becoming the first automaker to use what is called an advanced automotive aluminum commercially. (Ford Doubles Down on Micromill Aluminum with Alcoa) General Motors then decided to short cycle its recently all-new 2014 Chevrolet Silverado and GMC Sierra pickup trucks in response to Ford’s success with alternate materials and pending fuel economy regulations. (Ford Finally Will Offer F-150 Diesel Engines)

BMW Group claimed the Module category with the first 3D printed metal component used in a production series vehicle. This resulted in a 44% component weight savings on the 2018 BMW i8 Roadster.

Asahi Kasei Corporation’s Super Lightweight Pedal Bracket for the Mazda MX-5.

Sika Automotive’s Ultra Lightweight Constrained Layer Material System, and United States Steel Corporation’s Martensitic Advanced High Strength Steel, dubbed Mart-Ten1500 took the top honors in the Enabling Technology category.

The award for the new Future of Lightweighting category, chosen by MBS attendees, went to American Axle & Manufacturing, Inc. (AAM) for its Quantum Driveline Architecture program.

“Nominations from OEMs, suppliers, materials technology companies, start-ups and academia demonstrate the tremendous and varied weight reduction effort being achieved across the global automotive industry,” said judging chair Carla Bailo, President and CEO of CAR. “We were also thrilled at the response to the new Future of Lightweighting category introduced this year, which highlighted some highly innovative solutions holding great promise to advance fuel efficiency and automotive sustainability.”

The General Motors team applied in engineering and biz speak a multi-disciplinary optimization CAE approach, a higher percentage of advanced high strength steels, and new assembly methods in the development of the 2019 Chevrolet Silverado cab and frame to win the Full Vehicle award. In addition to the 450 pounds (204.5 kilograms) overall weight savings, General Motors claims 23% more storage space, greater dynamic stiffness, improved corrosion prevention, better NVH performance, and increased impact protection on the 2019 Silverado.

The Module category on vehicle systems, subsystems and components, was claimed by BMW Group for its 2018 BMW i8 Roadster for its metal 3D printed convertible roof bracket. This is the first time a metal 3D-printed part has been used in a series production vehicle. Produced with Selective Laser Melting (SLM) technology without needing any support structures, it was also the first time a topology-optimized design has been translated nearly 1:1 into a series production vehicle – claiming a 44% weight savings and a tenfold stiffness increase.

For the Enabling Technology category, that focuses on technological advances that allows manufacturers to save weight, the independent judging panel found the competition too tight and elected to recognize three award winners: Asahi Kasei Corporation with Mazda Corporation, Sika Automotive, and United States Steel Corporation.

Asahi Kasei’s winning entry was a brake pedal bracket for the Mazda MX-5 that was designed using glass fiber reinforced polyamide 66. The new injection-molded design required the Asahi Kasei and Mazda worked for the removal of unnecessary metal parts to realize a weight savings of 83%.

Sika Automotive’s winning entry was an ultra-lightweight constrained layer material system for structure-borne noise damping. Typical materials for structure-borne noise damping have an area weight of 5 kg/sqm, which was reduced by up to 80% in mid-sized sedans, such as the BMW i8, Audi Q7, and Daimler A-Class, when using Sika’s new ultra-lightweight materials.

U.S. Steel’s winning entry of Martensitic Advanced High Strength Steels for Low Mass Structural Components, Mart- have recently been introduced to the automotive market with ultimate tensile strengths exceeding 1,500 MPa. U.S. Steel’s advances in continuous annealing technology have enabled the Gigapascal strength to be achieved consistently and repeatedly in mass production to offer more than 10% in weight savings.

The Future of Lightweighting category was introduced this year to recognize innovative ideas, processes, materials and technologies that have significant potential to support light-weighting initiatives but have yet to be leveraged on a production vehicle platform. American Axle & Manufacturing was the inaugural award winner in this category for its Quantum Driveline Architecture. This is said to be a unique integration of proven materials and technologies to reduce the mass of light duty pickup rear axle systems by 35%, increase transmitted power efficiency, and deliver good NVH performance.

“Our judging panel had a very difficult task selecting this year’s award winners among so many high-quality entries,” said Richard Yen, Senior Vice President of Global Automotive and Industry Verticals at Altair. “ It’s a rewarding experience each year to witness how simulation-driven design strategies, new materials and advanced manufacturing processes are improving automotive light-weighting by offering new opportunities to innovate weight efficient products from the start.”

Pingback: Asahi Kasei and Honda to Make Lithium-ion Battery Separators | AutoInformed