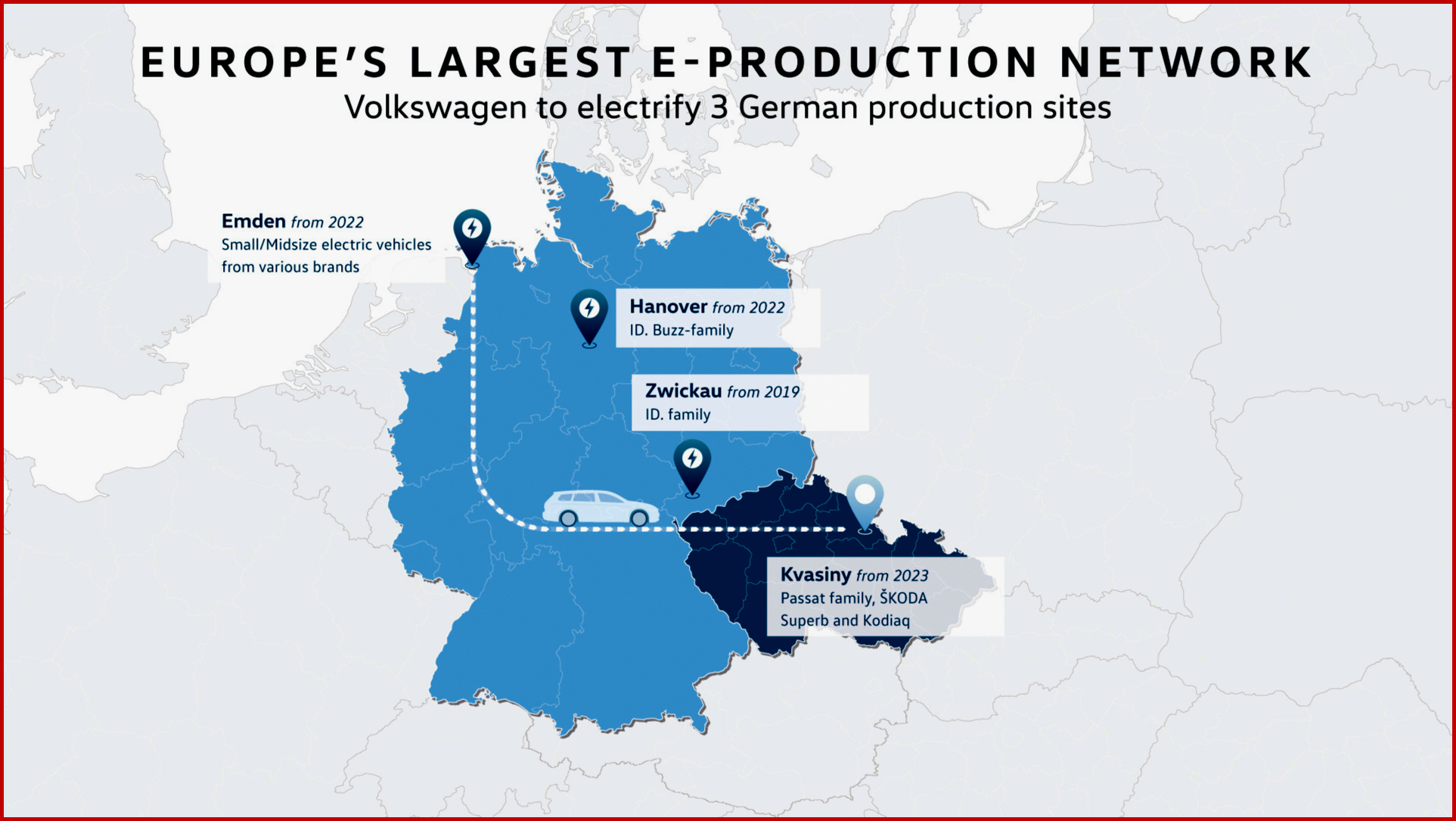

The Supervisory Board of Volkswagen Aktiengesellschaft has approved new production assignment plans that ultimately will eliminate assembly jobs. The plants in Emden and Hanover will be converted to build electric vehicles: models from the ID. Family. They will begin rolling off the assembly lines in 2022. In order to serve growth in Europe going forward, the Group will be expanding its production capacity post-2022 with an additional plant in Eastern Europe. WV Group has 660,000 employees all over the world – 290,000 of them in Germany.

In the future, electric small cars and sedans from several brands will be built in Emden, while Hanover will specialize in the production of the ID. BUZZ family, in addition to building vehicles with conventional drives. ID. BUZZ, a VW Microbus like EV, will arrive at dealerships after a compact four-door I.D. model in 2022. Volkswagen is mainly targeting the markets in North America, Europe and China with both the I.D. BUZZ and the I.D. family overall.

Oliver Blume, the Volkswagen AG Board of Management Member for Group Production, commented: “We have redefined the strategic guideposts for future plant assignment. We are making our plants fit for the future. Among other things, this includes bundling cross-brand product families to maximize synergies and cost benefits. That is how we will be realizing the full potential of the Volkswagen Group.”

All-electric cars will begin leaving the assembly lines in Emden and Hanover from 2022: “German plants are particularly well suited to making the transformation to the production of electric vehicles, given the high manufacturing expertise and qualification level of our employees. We are aligning the three plants in Zwickau, Emden and Hanover to our electrification strategy and thereby laying the groundwork for expanding our electric fleet and thus meeting the CO2 targets,” Blume continued.

Production of the Volkswagen Passat family will be moved to the ŠKODA plant in Kvasiny, Czech Republic. These models will be built there together with the ŠKODA Superb and Kodiaq from 2023. The ŠKODA Karoq and the SEAT Ateca, currently produced in Kvasiny, will be transferred to a new Group multi-brand plant. The Group is looking for a new location in Eastern Europe.

The Group and General Works Council Chairman, Bernd Osterloh said: “I am particularly proud that we have succeeded in locating a large share of e-mobility production at our plants here in Germany, because the markets in Germany and Western Europe, along with China and the USA, will lead the way in introducing electric vehicles.

The transition to e-mobility means fewer jobs as a result. That is something the Works Council has said on several occasions. Many VW workers, particularly in Emden and Hanover, are worried about the transformation. A ten-year employment guarantee excludes compulsory redundancies until the end of 2028. The Works council claims “adjustments via the demographic curve so that no one loses their job,” is part of the plan.

VW says the most important criteria for plant assignment are optimal utilization of existing capacity, platform orientation and volume bundling. As a result, flexible multi-brand plants will become increasingly common in order to harness the advantages of the flexible production network.

Reusing existing resources and factory structures and to cross-brand standardization to increase productivity and cut factory costs and investments are key elements of the plan

Group Production has targeted a 30% increase in productivity by 2025. The environmental impact of Group plants is to be almost halved within the same time-frame. “We have set ourselves clear and ambitious goals”, Blume said. “Production must be a strategic competitive advantage for the Group.”

Pingback: Electrify America, Hubject Announce Launch of Plug&Charge | AutoInformed