Latest step in the EV sourcing wars underway at all automakers.

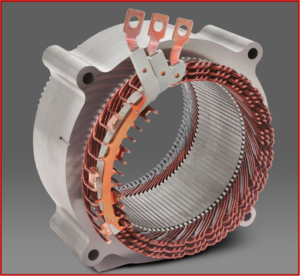

General Motors announced today plans to invest ~$154 million in its Western New York Lockport Components plant to renovate the facility and purchase and install new machinery and equipment used in the production of the stator module. Stators are key components in an electric motor. Electric motors will be used in a variety – currently 30 – of GM’s future Ultium Platform-based electric trucks and SUVs. Facility renovations begin immediately.

EV production – particularly final assembly is a huge concern for unions globally. “It’s pretty easy to build an EV since there are fewer components, and there are no EPA requirements or fluids,” Joe McCabe the CEO of AutoForecast Solutions told AutoInformed at a meeting of the International Motor Press Association earlier this week. Robots or non-skilled labor can do most of the work. (read AutoInformed on GM Cuts More Deals on Materials, Factories for EV Motors)

It’s the latest step in the EV sourcing wars that are underway at all automakers since Global Warming requires the conversion of virtually all transportation modes to EVs. Lurking in the background of this issue is a larger national security problem that sees China spending twice as much on research and development as the US. A bill to restore and increase US government sponsored scientific R&D has passed the Senate but is being held up by infighting among Democrats in the House of Representatives, which is representative of our ongoing politically-based dysfunctional government. See David Leonard of the New York Times.

As Lockport prepares for electric motor component production, the plant will continue to build a variety of components that support GM’s current truck and SUV production. It currently produces radiators, condensers, heater cores, evaporators, HVAC modules, oil coolers and other parts used in a variety of GM trucks. GM currently estimates Lockport Components will add approximately 230 positions between 2023 and 2026. Actual staffing levels will come closer to the start of production as the facility transitions to support EV motor component production.

Lockport Components was founded in 1910 as the Harrison Radiator Company for the purpose of designing, manufacturing, and selling automotive radiators and components. With more than 1,500 employees, the site is represented by UAW Locals 686 and 55.

AutoInformed on

Previously announced GM supply chain collaborations:

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

GM Lockport Components Plant to Build EV Stators

Latest step in the EV sourcing wars underway at all automakers.

General Motors announced today plans to invest ~$154 million in its Western New York Lockport Components plant to renovate the facility and purchase and install new machinery and equipment used in the production of the stator module. Stators are key components in an electric motor. Electric motors will be used in a variety – currently 30 – of GM’s future Ultium Platform-based electric trucks and SUVs. Facility renovations begin immediately.

EV production – particularly final assembly is a huge concern for unions globally. “It’s pretty easy to build an EV since there are fewer components, and there are no EPA requirements or fluids,” Joe McCabe the CEO of AutoForecast Solutions told AutoInformed at a meeting of the International Motor Press Association earlier this week. Robots or non-skilled labor can do most of the work. (read AutoInformed on GM Cuts More Deals on Materials, Factories for EV Motors)

It’s the latest step in the EV sourcing wars that are underway at all automakers since Global Warming requires the conversion of virtually all transportation modes to EVs. Lurking in the background of this issue is a larger national security problem that sees China spending twice as much on research and development as the US. A bill to restore and increase US government sponsored scientific R&D has passed the Senate but is being held up by infighting among Democrats in the House of Representatives, which is representative of our ongoing politically-based dysfunctional government. See David Leonard of the New York Times.

As Lockport prepares for electric motor component production, the plant will continue to build a variety of components that support GM’s current truck and SUV production. It currently produces radiators, condensers, heater cores, evaporators, HVAC modules, oil coolers and other parts used in a variety of GM trucks. GM currently estimates Lockport Components will add approximately 230 positions between 2023 and 2026. Actual staffing levels will come closer to the start of production as the facility transitions to support EV motor component production.

Lockport Components was founded in 1910 as the Harrison Radiator Company for the purpose of designing, manufacturing, and selling automotive radiators and components. With more than 1,500 employees, the site is represented by UAW Locals 686 and 55.

AutoInformed on

Previously announced GM supply chain collaborations:

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.