Click for more.

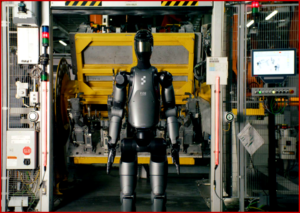

The BMW Group said today that it is exploring the use of humanoid robots in production for the first time. During a trial run lasting several weeks at BMW Group Plant Spartanburg, the latest humanoid robot called Figure 02 from California company Figure successfully inserted sheet metal parts into specific fixtures, which were then assembled as part of the chassis. There is no definite timetable established for bringing Figure robots to the plant.

“The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization,” says Milan Nedeljković, Member of the Board of Management for Production at BMW AG.

This is all part of the so-called BMW iFACTORY, a program to develop production methods of the of the future. During the trial run, the BMW Group said it gained valuable knowledge of what requirements must be met in order to be able to integrate so-called multi-purpose robots in an existing production system. This includes how humanoid robots communicate with the system under real conditions. After the first use in automobile production, the experts at the BMW Group and Figure are collaborating to prepare Figure for future applications in production and continuing to develop the robots, based on the findings.*

“We are excited to unveil Figure 02, our second-generation humanoid robot, which recently completed successful testing at the BMW Group Plant Spartanburg. Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously,” says Brett Adcock, Founder and CEO of Figure

Figure 02 is claimed to be the world’s most advanced humanoid robot currently available on the market. The combination of two-legged mobility and advanced dexterity means that the Figure 02 is ideally suited for use in areas with physically demanding, unsafe, or repetitive processes, thereby improving ergonomics and safety for associates. Figure02 has three times the processing power of its predecessor 01, improved voice communication, better cameras, microphones, and sensors, a high-performance battery, and fourth-generation human-scale hands with 16-degrees of freedom per hand and human-equivalent strength.

The robot is said to be capable of fully autonomous execution of human-like and two-handed tasks requiring varied and dynamic manipulation, complex grasping, and coordination of both hands in unison. It is able place various complex parts with accuracy measured in millimeters and can walk dynamically leveraging efficiencies of the robot’s design.

*AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

BMW and California Robotics Firm Testing Humanoid Robot

Click for more.

The BMW Group said today that it is exploring the use of humanoid robots in production for the first time. During a trial run lasting several weeks at BMW Group Plant Spartanburg, the latest humanoid robot called Figure 02 from California company Figure successfully inserted sheet metal parts into specific fixtures, which were then assembled as part of the chassis. There is no definite timetable established for bringing Figure robots to the plant.

“The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization,” says Milan Nedeljković, Member of the Board of Management for Production at BMW AG.

This is all part of the so-called BMW iFACTORY, a program to develop production methods of the of the future. During the trial run, the BMW Group said it gained valuable knowledge of what requirements must be met in order to be able to integrate so-called multi-purpose robots in an existing production system. This includes how humanoid robots communicate with the system under real conditions. After the first use in automobile production, the experts at the BMW Group and Figure are collaborating to prepare Figure for future applications in production and continuing to develop the robots, based on the findings.*

“We are excited to unveil Figure 02, our second-generation humanoid robot, which recently completed successful testing at the BMW Group Plant Spartanburg. Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously,” says Brett Adcock, Founder and CEO of Figure

Figure 02 is claimed to be the world’s most advanced humanoid robot currently available on the market. The combination of two-legged mobility and advanced dexterity means that the Figure 02 is ideally suited for use in areas with physically demanding, unsafe, or repetitive processes, thereby improving ergonomics and safety for associates. Figure02 has three times the processing power of its predecessor 01, improved voice communication, better cameras, microphones, and sensors, a high-performance battery, and fourth-generation human-scale hands with 16-degrees of freedom per hand and human-equivalent strength.

The robot is said to be capable of fully autonomous execution of human-like and two-handed tasks requiring varied and dynamic manipulation, complex grasping, and coordination of both hands in unison. It is able place various complex parts with accuracy measured in millimeters and can walk dynamically leveraging efficiencies of the robot’s design.

*AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.