Click for more.

The BMW Group said today that it continues to invest in e-component production at Plant. A leasehold contract has now been signed for an area of land outside the plant premises, on the northern industrial estate, which is also home to the existing facility. The new plot for BMW use consists of 12 hectares, eight of which will be built on during the first stage of construction. This will produce a logistics hall for the current fifth-generation high-voltage batteries and an office building, both of which are due to reach completion in mid-2024.

“Leipzig continues to power ahead. Making the BMW i3, we were the BMW Group’s pioneer in electromobility. Now, with the development of e-component production and the upcoming launch of the MINI Countryman, the future is already taking shape,” said Petra Peterhänsel, Plant Director.

During the first stage of construction, a warehouse, a two-story office building and a loading tunnel with a combined gross area of 38,000 m2 will be erected. There are also plans for a second construction stage, which will take the total investment to as much as €100 million, BMW claimed. When all the construction work is complete, the new buildings at the Supply Center North will provide workplaces for ~500 employees.

Click for more.

By 2026 the BMW Group aims for at least one in three new cars sold to be fully electric. Plant Leipzig is already key in supplying e-components for the production network. It provides one in three battery modules for the BMW Group’s fully electric vehicles. These include the BMW iX1, the BMW i5 and the BMW iX. With the new hall as a logistics center for high-voltage batteries, Plant Leipzig is expanding with a building that meets all the structural requirements for handling high-voltage components. (AutoInformed: BMW Group to Open Cell Manufacturing Center this Fall)

During planning, the logistics hall BMW claims that the team applied stringent environmental standards that go beyond legal requirements. The buildings will be powered not by fossil fuels. Photovoltaic systems on the roof will generate ~3000 kW in peak operations. In addition, the hall will be heated by a heat pump. The office building will have a green roof, and trees at strategic points along the façade will keep indoor temperatures cool when the weather outside is hot.

The outside space will be landscaped with more than 5700 new shrubs and trees. This will continue the City of Leipzig and the BMW Group’s efforts to add to the so-called green ring around the plant on the Northern Industrial Estate. Outdoor areas will be illuminated by insect-friendly lights, and parking spaces will be equipped with electric charging points for cars and trucks so that electric heavy goods vehicles can operate between the plant and warehouse.

E-Component Production – The Future of Leipzig

Behind the additions that are currently being made to Plant Leipzig, both on the premises and off, is e-component production. Measures will safeguard existing jobs and increase the number of new ones. At the moment more than 800 employees work in e-component production in Leipzig – projected at more than 1000 by 2024. Further jobs will be created with service providers, BMW said.

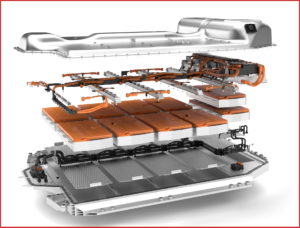

During 2024 BMW Plant Leipzig will run all three stages of the high-voltage battery production process: cell coating, module production and high-voltage battery assembly. E-component production capacity has been steadily increasing since 2021, and at present battery cells are coated and assembled into modules there. One in three battery modules for BMW Group fully electric vehicles already comes from Leipzig today. A battery assembly system is currently under construction, expected to go online early next year. The BMW Group said it is investing up to €1 billion euros in extending e-component production at Leipzig.

BMW i3 production is now phased out. Plant Leipzig will launch its next fully electric model, the new MINI Countryman during 2024. The crossover will come with a choice of combustion engines or a fully electric drive with the high-voltage batteries being made in Plant Leipzig’s workshops.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

BMW Group Expanding EV Battery Plant Leipzig

Click for more.

The BMW Group said today that it continues to invest in e-component production at Plant. A leasehold contract has now been signed for an area of land outside the plant premises, on the northern industrial estate, which is also home to the existing facility. The new plot for BMW use consists of 12 hectares, eight of which will be built on during the first stage of construction. This will produce a logistics hall for the current fifth-generation high-voltage batteries and an office building, both of which are due to reach completion in mid-2024.

“Leipzig continues to power ahead. Making the BMW i3, we were the BMW Group’s pioneer in electromobility. Now, with the development of e-component production and the upcoming launch of the MINI Countryman, the future is already taking shape,” said Petra Peterhänsel, Plant Director.

During the first stage of construction, a warehouse, a two-story office building and a loading tunnel with a combined gross area of 38,000 m2 will be erected. There are also plans for a second construction stage, which will take the total investment to as much as €100 million, BMW claimed. When all the construction work is complete, the new buildings at the Supply Center North will provide workplaces for ~500 employees.

Click for more.

By 2026 the BMW Group aims for at least one in three new cars sold to be fully electric. Plant Leipzig is already key in supplying e-components for the production network. It provides one in three battery modules for the BMW Group’s fully electric vehicles. These include the BMW iX1, the BMW i5 and the BMW iX. With the new hall as a logistics center for high-voltage batteries, Plant Leipzig is expanding with a building that meets all the structural requirements for handling high-voltage components. (AutoInformed: BMW Group to Open Cell Manufacturing Center this Fall)

During planning, the logistics hall BMW claims that the team applied stringent environmental standards that go beyond legal requirements. The buildings will be powered not by fossil fuels. Photovoltaic systems on the roof will generate ~3000 kW in peak operations. In addition, the hall will be heated by a heat pump. The office building will have a green roof, and trees at strategic points along the façade will keep indoor temperatures cool when the weather outside is hot.

The outside space will be landscaped with more than 5700 new shrubs and trees. This will continue the City of Leipzig and the BMW Group’s efforts to add to the so-called green ring around the plant on the Northern Industrial Estate. Outdoor areas will be illuminated by insect-friendly lights, and parking spaces will be equipped with electric charging points for cars and trucks so that electric heavy goods vehicles can operate between the plant and warehouse.

E-Component Production – The Future of Leipzig

Behind the additions that are currently being made to Plant Leipzig, both on the premises and off, is e-component production. Measures will safeguard existing jobs and increase the number of new ones. At the moment more than 800 employees work in e-component production in Leipzig – projected at more than 1000 by 2024. Further jobs will be created with service providers, BMW said.

During 2024 BMW Plant Leipzig will run all three stages of the high-voltage battery production process: cell coating, module production and high-voltage battery assembly. E-component production capacity has been steadily increasing since 2021, and at present battery cells are coated and assembled into modules there. One in three battery modules for BMW Group fully electric vehicles already comes from Leipzig today. A battery assembly system is currently under construction, expected to go online early next year. The BMW Group said it is investing up to €1 billion euros in extending e-component production at Leipzig.

BMW i3 production is now phased out. Plant Leipzig will launch its next fully electric model, the new MINI Countryman during 2024. The crossover will come with a choice of combustion engines or a fully electric drive with the high-voltage batteries being made in Plant Leipzig’s workshops.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.