Click to enlarge.

McLaren Automotive* said today it has developed a world-first application of an aerospace industry composites manufacturing method scaled appropriately for volume supercar manufacturing. Deployed at the McLaren Composites Technology Center (MCTC) in Sheffield, UK, the new Automated Rapid Tape (ART) production method produces McLaren ART carbon fiber structures that can be optimized to be lighter, stiffer and stronger via advanced structural optimization. They are also produced with less waste material generation.

“With more than four decades of experience in exploiting the benefits of carbon fiber as an enabler of light weight, high performance, and structural strength, McLaren has driven key developments in racing and automotive uses for the material, making it not only the standard across the Formula 1 grid, but bringing it to the road, too. Every single McLaren ever made has been based on a carbon fiber monocoque, while McLaren also maximizes the benefits of this lightweight, strong and durable material in body structures and aerodynamic systems, to unlock maximum performance and thrilling driving dynamics without compromise,” McLaren said.

“The aerospace industry uses ultra-precise manufacturing methods to build highly tailored carbon fiber structures for the latest generation of air jetliners and fighter aircraft, particularly for large, crucial parts such as aircraft fuselage and wings. This is achieved via the robotic depositing of composite tapes to layer structures, over traditional hand layup using pre-impregnated materials. And it is a rapid pace, ‘high rate’ version of this production method that McLaren has developed and now integrated into its manufacturing capabilities,” McLaren said.

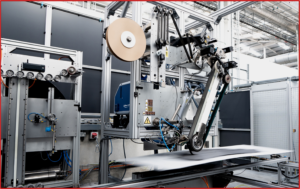

Unlike the aerospace industry method of using robotic arms to layer composite tapes, McLaren’s Automated Rapid Tape method instead employs a specially designed machine using a fixed deposition head and a rapidly moving bed capable of rotation, which is a faster manufacturing process suitable for automotive purposes and high-rate composites manufacturing.

Automated Rapid Tape Highlights

- Greater design freedom for engineers: McLaren ART enables tailored fiber placement, creating new possibilities relating to load bearing or stiffness requirements not possible by conventional methods. It encourages innovation by freeing engineers from uniform material constraints. Specific adjustment of fiber orientation within the composite material allows for anisotropic stiffness – rigidity can be enhanced in specific directions while flexibility can be maintained elsewhere. This allows new ways to design highly loaded, complex aerodynamic components.

- It also allows for optimized strength-to-weight: Fibers can be concentrated in areas subject to high stress or load, such as joints, edges, or connection points, in turn allowing for the removal of unnecessary material in low-stress regions.

- Carbon fiber structures that are created with less waste: As measured lengths of dry composite tape are laid down when building out a part made of McLaren ART carbon fiber, there is a significant reduction in the generation of irregular-shaped off-cuts that cannot be reused. Up to 95% of the raw dry tape material used to layer a component goes into the final part. The automated process also reduces positioning inaccuracies and material loss caused by human error, ensuring that the final layup is within design tolerances, in turn minimizing rejected parts. The automated element of the Automated Rapid Tape machine provides real-time monitoring and control, ensuring consistent process parameters and optimized part quality.

- Enables Greater Use of Carbon Fiber: The advantages Automated Rapid Tape technology can deliver in terms of manufacturing time and reduced costs creates the possibility of greater use of carbon fiber, in more areas of a vehicle. Beyond the carbon tub, wider use of ultra-lightweight body panels constructed of McLaren ART carbon fiber become more feasible and cost effective.

AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

McLaren Automotive Using Aerospace-Grade Carbon Fiber

Click to enlarge.

McLaren Automotive* said today it has developed a world-first application of an aerospace industry composites manufacturing method scaled appropriately for volume supercar manufacturing. Deployed at the McLaren Composites Technology Center (MCTC) in Sheffield, UK, the new Automated Rapid Tape (ART) production method produces McLaren ART carbon fiber structures that can be optimized to be lighter, stiffer and stronger via advanced structural optimization. They are also produced with less waste material generation.

“With more than four decades of experience in exploiting the benefits of carbon fiber as an enabler of light weight, high performance, and structural strength, McLaren has driven key developments in racing and automotive uses for the material, making it not only the standard across the Formula 1 grid, but bringing it to the road, too. Every single McLaren ever made has been based on a carbon fiber monocoque, while McLaren also maximizes the benefits of this lightweight, strong and durable material in body structures and aerodynamic systems, to unlock maximum performance and thrilling driving dynamics without compromise,” McLaren said.

“The aerospace industry uses ultra-precise manufacturing methods to build highly tailored carbon fiber structures for the latest generation of air jetliners and fighter aircraft, particularly for large, crucial parts such as aircraft fuselage and wings. This is achieved via the robotic depositing of composite tapes to layer structures, over traditional hand layup using pre-impregnated materials. And it is a rapid pace, ‘high rate’ version of this production method that McLaren has developed and now integrated into its manufacturing capabilities,” McLaren said.

Unlike the aerospace industry method of using robotic arms to layer composite tapes, McLaren’s Automated Rapid Tape method instead employs a specially designed machine using a fixed deposition head and a rapidly moving bed capable of rotation, which is a faster manufacturing process suitable for automotive purposes and high-rate composites manufacturing.

Automated Rapid Tape Highlights

AutoInformed on

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.