In Stuttgart this morning Mercedes-Benz said it continues to realign its global production network* towards electric vehicles as it prepares to go fully electric by the end of the decade. That is caveat “wherever market conditions allow.” Mercedes-Benz is changing its production setup for electric drive systems – batteries**, electric drive units and axles – starting in 2024, following the realigned production setup for electric vehicles based on future vehicle architectures announced earlier this year. (AutoInformed.com: Mercedes-Benz Digital ESG Touts Cutting CO2 Emissions; Mercedes-Benz – New Platforms Electric Only From 2025)

“Plug-in hybrids and fully electric vehicles are expected to account for around half of unit sales by as soon as 2025. Conventional drive units will remain part of the Mercedes-Benz drive portfolio in the medium term. With increasing electrification, demand will shift towards e-mobility components, batteries and electric drive systems.,” Mercedes said.

Click for more information.

The new Mercedes-Benz powertrain production network was achieved following what were likely dicey discussions with German employee representatives. Mercedes says this resulted in agreements to further increase flexibility and efficiency at the various locations, paving the way for securing the future of the plants. In line with the implementation of the Mercedes-Benz Business Plan, the company is investing a mid-single-digit billion-euro amount in its European powertrain production locations. Thus far worker protest or strikes are apparently non-existent.

“The path towards sustainable, all-electric mobility has begun. As the General Works Council, we are committed to shaping this change, which is both a challenge and an opportunity, in a fair and socially just manner. In the realignment of the global production setup with regard to all-electric vehicle architectures, we demanded from the outset: The German locations must play an essential role. In the summer, we were already able to agree on visions of the future for the vehicle plants.

“It was always clear to us that we wanted to achieve this for the powertrain locations as well. Our persistence has paid off. I am pleased that we have created security and clear prospects for our colleagues in the powertrain production network,” said Ergun Lümali, Dep. Chairman of the Supervisory Board and Chairman of the Works Council of Mercedes-Benz Group AG

*The Mercedes-Benz powertrain production network

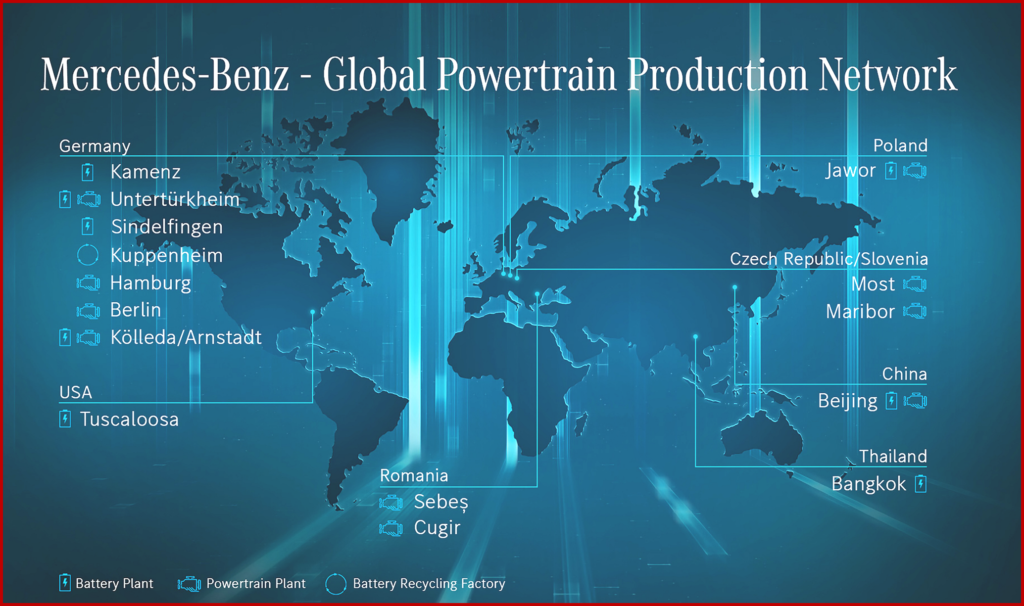

The Mercedes-Benz powertrain production network consists of 14 locations on three continents, providing drive systems, major assemblies and components for the entire Mercedes-Benz powertrain portfolio. It supplies the Mercedes-Benz body plants around the world. A planned battery recycling plant at the Kuppenheim location is also part of this network. During 2022, Mercedes-Benz has been producing on a CO2-neutral basis in all its own plants worldwide and purchasing electricity that comes exclusively from renewable sources. In addition, the company aims to increase the generation of renewable energy at its locations.

** The new battery factory in Bibb County near the Mercedes-Benz vehicle plant in Tuscaloosa, Alabama (USA), started operations this year. It produces efficient battery systems for the all-electric EQS SUV and EQE SUV, which are already in production starting this year.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Mercedes-Benz Outlines EV Drive Systems Production Sites

In Stuttgart this morning Mercedes-Benz said it continues to realign its global production network* towards electric vehicles as it prepares to go fully electric by the end of the decade. That is caveat “wherever market conditions allow.” Mercedes-Benz is changing its production setup for electric drive systems – batteries**, electric drive units and axles – starting in 2024, following the realigned production setup for electric vehicles based on future vehicle architectures announced earlier this year. (AutoInformed.com: Mercedes-Benz Digital ESG Touts Cutting CO2 Emissions; Mercedes-Benz – New Platforms Electric Only From 2025)

“Plug-in hybrids and fully electric vehicles are expected to account for around half of unit sales by as soon as 2025. Conventional drive units will remain part of the Mercedes-Benz drive portfolio in the medium term. With increasing electrification, demand will shift towards e-mobility components, batteries and electric drive systems.,” Mercedes said.

Click for more information.

The new Mercedes-Benz powertrain production network was achieved following what were likely dicey discussions with German employee representatives. Mercedes says this resulted in agreements to further increase flexibility and efficiency at the various locations, paving the way for securing the future of the plants. In line with the implementation of the Mercedes-Benz Business Plan, the company is investing a mid-single-digit billion-euro amount in its European powertrain production locations. Thus far worker protest or strikes are apparently non-existent.

“The path towards sustainable, all-electric mobility has begun. As the General Works Council, we are committed to shaping this change, which is both a challenge and an opportunity, in a fair and socially just manner. In the realignment of the global production setup with regard to all-electric vehicle architectures, we demanded from the outset: The German locations must play an essential role. In the summer, we were already able to agree on visions of the future for the vehicle plants.

“It was always clear to us that we wanted to achieve this for the powertrain locations as well. Our persistence has paid off. I am pleased that we have created security and clear prospects for our colleagues in the powertrain production network,” said Ergun Lümali, Dep. Chairman of the Supervisory Board and Chairman of the Works Council of Mercedes-Benz Group AG

*The Mercedes-Benz powertrain production network

The Mercedes-Benz powertrain production network consists of 14 locations on three continents, providing drive systems, major assemblies and components for the entire Mercedes-Benz powertrain portfolio. It supplies the Mercedes-Benz body plants around the world. A planned battery recycling plant at the Kuppenheim location is also part of this network. During 2022, Mercedes-Benz has been producing on a CO2-neutral basis in all its own plants worldwide and purchasing electricity that comes exclusively from renewable sources. In addition, the company aims to increase the generation of renewable energy at its locations.

** The new battery factory in Bibb County near the Mercedes-Benz vehicle plant in Tuscaloosa, Alabama (USA), started operations this year. It produces efficient battery systems for the all-electric EQS SUV and EQE SUV, which are already in production starting this year.

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.