Click for more Niron.

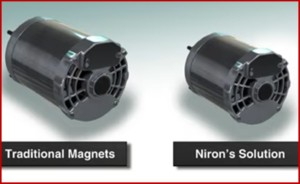

General Motors (NYSE: GM) said today that it will work with Niron Magnetics* of Minneapolis, which has developed the world’s first and only permanent magnet with automotive-grade power that is free from critical materials, including rare or heavy rare earth minerals.

“We believe Niron’s unique technology can play a key role in reducing rare earth minerals from EV motors and help us further scale our North American-based supply chain for EVs,” said Anirvan Coomer, president of GM Ventures. “Our path to an all-electric future will be enabled not only by our own research and development efforts, but also by investing in next generation technology from startups and established companies outside our four walls.”

Niron’s proprietary Clean Earth Magnet® technology is based on iron nitride, a plentiful and affordable material with “real potential for commercial use in future EVs,” GM said. The permanent magnets in EV motor rotors are typically made from rare earth minerals such as terbium, dysprosium, praseodymium and neodymium, which are expensive and currently processed almost entirely overseas. A new vehicle can use hundreds of magnets. This technology can cut their material cost in half it’s claimed.

GM and Niron have completed a strategic partnership agreement to co-develop Clean Earth Magnet motor technology that can be used in future GM EVs. GM Ventures has also made an investment in Niron, which will join its more than 30 portfolio companies. The investment will support the scaling of Niron’s manufacturing and commercialization of their sustainable magnets. Chinese owned Volvo is also an investor in Niron. The new funding from GM Ventures, also joins Stellantis Ventures, Shakopee Mdewakanton Sioux Community, University of Minnesota, among others to help accelerate commercialization of Niron’s Clean Earth Magnet® technology

“GM invented rare earth permanent magnets nearly 40 years ago, and now we’re working together to bring the next generation of automotive magnet technology to market,” said Jonathan Rowntree, CEO of Niron Magnetics. “We think that our Clean Earth Magnets can help GM in its goal to put everyone in an EV.”

*Niron Magnetics says: “For high performance applications, magnets made of rare-earth materials are the most widely used today (such as NdFeB magnets). However, the mining, extraction, and manufacturing processes are labor intensive, expensive, and environmentally damaging. Due to persistent supply chain and geopolitical issues, the prices of these materials have been historically unstable and have surged over the last year.

“Niron’s proprietary Clean Earth Magnet materials possess inherently higher magnetization and can be produced at a lower cost. Using a patented, scalable process, Niron will produce high powered magnets using commonly available iron and nitrogen raw materials that can be sourced globally and sustainably.

“Our manufacturing process combines breakthroughs in nanomaterials with well understood, mature metallurgical methods to deliver high performance magnets at half the cost.”

Niron Magnetics – Potential Automotive Applications

- BEV, HEV, PHEV traction motors

- Belt or integrated starter generators

- Power seat, window, lock, mirror, and sunroof motors

- Water pump motors

- Power liftgate motors

- Ignition coil motors

- Cooling fans

- Electric compressors

- Electric brakes

- Exhaust gas recirculation valves

- Power tilt steering

- Crank angle sensors

- Windshield wiper motors

- Other auto micro-motors

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

GM Announces Niron Magnetics Partnership for EV Motors

Click for more Niron.

General Motors (NYSE: GM) said today that it will work with Niron Magnetics* of Minneapolis, which has developed the world’s first and only permanent magnet with automotive-grade power that is free from critical materials, including rare or heavy rare earth minerals.

“We believe Niron’s unique technology can play a key role in reducing rare earth minerals from EV motors and help us further scale our North American-based supply chain for EVs,” said Anirvan Coomer, president of GM Ventures. “Our path to an all-electric future will be enabled not only by our own research and development efforts, but also by investing in next generation technology from startups and established companies outside our four walls.”

Niron’s proprietary Clean Earth Magnet® technology is based on iron nitride, a plentiful and affordable material with “real potential for commercial use in future EVs,” GM said. The permanent magnets in EV motor rotors are typically made from rare earth minerals such as terbium, dysprosium, praseodymium and neodymium, which are expensive and currently processed almost entirely overseas. A new vehicle can use hundreds of magnets. This technology can cut their material cost in half it’s claimed.

GM and Niron have completed a strategic partnership agreement to co-develop Clean Earth Magnet motor technology that can be used in future GM EVs. GM Ventures has also made an investment in Niron, which will join its more than 30 portfolio companies. The investment will support the scaling of Niron’s manufacturing and commercialization of their sustainable magnets. Chinese owned Volvo is also an investor in Niron. The new funding from GM Ventures, also joins Stellantis Ventures, Shakopee Mdewakanton Sioux Community, University of Minnesota, among others to help accelerate commercialization of Niron’s Clean Earth Magnet® technology

“GM invented rare earth permanent magnets nearly 40 years ago, and now we’re working together to bring the next generation of automotive magnet technology to market,” said Jonathan Rowntree, CEO of Niron Magnetics. “We think that our Clean Earth Magnets can help GM in its goal to put everyone in an EV.”

*Niron Magnetics says: “For high performance applications, magnets made of rare-earth materials are the most widely used today (such as NdFeB magnets). However, the mining, extraction, and manufacturing processes are labor intensive, expensive, and environmentally damaging. Due to persistent supply chain and geopolitical issues, the prices of these materials have been historically unstable and have surged over the last year.

“Niron’s proprietary Clean Earth Magnet materials possess inherently higher magnetization and can be produced at a lower cost. Using a patented, scalable process, Niron will produce high powered magnets using commonly available iron and nitrogen raw materials that can be sourced globally and sustainably.

“Our manufacturing process combines breakthroughs in nanomaterials with well understood, mature metallurgical methods to deliver high performance magnets at half the cost.”

Niron Magnetics – Potential Automotive Applications

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.