Overall problem rates for audio/entertainment/navigation systems in 2011 are 18% higher than in 2010 and 28% higher than in 2009.

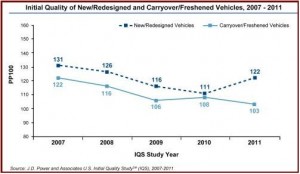

After a four year run of improving quality, the trend has reversed itself. The initial quality of 2011 new vehicles has declined considerably in the latest study. Launch models – vehicles that are all-new or have had major redesigns – saw ratings drop by 10% to an average of 122 PP100 in 2011 from 111 PP100 in 2010. This counters an improvement in the quality of newly launched models every year from 2007 to 2010.

Overall, initial quality improved to an average of 107 problems per 100 vehicles (PP100) in 2011 from 109 PP100 in 2010. That’s because carryover models – those that have had no significant redesign in the past year – had better initial quality than ever before. Owners of these vehicles report an average of just 103 PP100 in 2011, compared with 108 PP100 in 2010.

Lower PP100 scores indicate a lower rate of problem incidences and therefore higher initial quality, according to the J.D. Power and Associates 2011 U.S. Initial Quality Study (IQS) released today. The study has been conducted annually for the past 25 years.

“Expected reliability continues to be the single-most-important reason why new-vehicle buyers choose one model over another, and no manufacturer can afford to give consumers any doubts regarding the quality of their latest products,” said David Sargent, vice president of global vehicle research at J.D. Power and Associates.

Only seven all-new or redesigned models rank among the top three of their respective award segments, compared with 17 models in 2010, and only one launch model received a segment award this year versus five launch models in 2010.

Just one-fourth of redesigned models perform better than the outgoing previous-generation model did in 2010, and eight all-new models perform above their respective award segment average.

The decline in vehicle launch quality is evident in a number of areas, most notably the engine/transmission and audio/entertainment/navigation categories.

Power says there are two primary causes for this quality decline:

- With high fuel prices and more stringent government regulations, automakers are designing engine and transmission software to make their models as economical as possible. However, this sometimes leads to the engine or transmission “hesitating” when accelerating or changing gears, and consumers this year are reporting this as a problem more often than in past years.

- Automakers are also accelerating the introduction of multimedia technology into their models, including hands-free and voice-activation systems. Many consumers are attracted by this type of technology, which is perceived to enhance convenience and safety, but some vehicle owners report that their system is not intuitive and/or does not always function properly. (Ford Motor took a huge hit because of this.)

“Clearly, consumers are interested in having new technology in their vehicles, but automakers must ensure that the technology is ready for prime time,” said Sargent.

While overall vehicle quality continues to improve, the introduction of new technology is expected to continue to pose challenges for automakers. Overall problem rates for audio/entertainment/navigation systems in 2011 are 18% higher than in 2010 and 28% higher than in 2009.

Initial quality has been shown throughout the years to be an excellent predictor of long-term durability, which directly impacts consumer purchase decisions. The study captures problems experienced by owners in two distinct categories: design-related problems and defects and malfunctions.

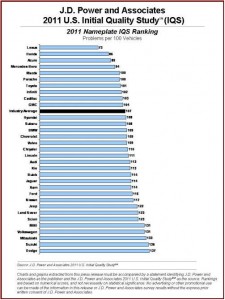

2011 IQS Ranking

Lexus leads the overall nameplate rankings with 73 PP100 on average. Following in the rankings are Honda (which improves to second rank position in 2011 from sixth in 2010 – its best ever performance.), Acura, Mercedes-Benz and Mazda (which improves to fifth rank position in 2011 from 18th in 2010), respectively. Land Rover posts the largest improvement in 2011, reducing problems by 47 PP100 from 2010.

Honda received seven segment awards for the Accord, Accord Crosstour, Civic (in a tie), Element, Fit, Insight (in a tie) and Ridgeline. Lexus receives four segment awards for the ES, GS, GX and LS models. For a second consecutive year, the Lexus LS has the fewest quality problems in the industry with just 54 PP100.

“Creating products of the highest quality and value is the foundation of our business, and it begins with a deep understanding of the customer,” said Tetsuo Iwamura, president & CEO of American Honda Motor Company after the results were announced.

Chevrolet, Ford and Mercedes-Benz receive two awards each. Chevrolet receives awards for the HHR and the Tahoe; Ford for the F-150 and the Taurus; and Mercedes-Benz for the GLK-Class and the E-Class cabriolet/coupe. Also receiving segment awards are the Cadillac Escalade; Chrysler Town & Country; Dodge Challenger; and Mazda MX-5 Miata.

Among all-new and redesigned models, the Hyundai Equus and Dodge Durango are notably strong performers, each ranking second in their respective segment.

Assembly Plant Awards

Three assembly plants receive Platinum Plant Quality Awards (in a three-way tie) for producing models yielding the fewest defects and malfunctions: the Toyota Motor Corporation Cambridge South, Ontario, Canada, plant (which produces the Lexus RX); the Toyota Motor Corporation Kyushu 2, Japan, plant (which produces the Lexus ES, IS and RX); and the Honda Motor Company plant in Greensburg, Ind. (which produces the Civic). These plants average just 24 PP100. Plant awards are based on average levels of defects and malfunctions and exclude design-related problems.

In the Europe and Africa region, Daimler’s Bremen 1, Germany, and East London, South Africa, plants each receive a Gold Plant Quality Award in a tie. The Bremen 1 plant produces the Mercedes-Benz C-Class, E-Class cabriolet/coupe and GLK-Class, while the East London plant produces the C-Class.

The 2011 U.S. Initial Quality Study is based on responses from more than 73,000 purchasers and lessees of new 2011 model-year cars, trucks and multi-activity vehicles surveyed after 90 days of ownership. The study is based on a 228-question battery designed to provide manufacturers with information to facilitate identifying problems and drive product improvement. The study was fielded between February and May 2011.