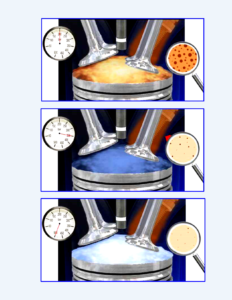

Click to Enlarge. Care must be taken because in the drive towards diesel-like efficiency, gasoline engines may come with diesel-like emissions and cost.

Diesel and gasoline share a common problem because there is a tricky trade-off to be made between emissions compliance and added cost. For gasoline, however, there is an additional dimension: CO₂ reduction. The main research on gasoline engines these days is, unsurprisingly, fuel efficiency, which directly correlates with CO2.

The gap with diesel is closing, but in more ways than just fuel efficiency. Expensive hardware, lean combustion, high pressure injection, compression-ignition – all quintessential characteristics of diesel engines – are now appearing on gasoline engines.

Efficient and hybridized gasoline should be the combustion-based alternative as diesel declines. Considering these added costs and complexities that have always been part of diesel, there is an unknown risk that the same pattern of reputational blight and penalties will occur on gasoline engines. This could/would accelerate the demise of the internal combustion engine while promoting electric vehicles.

There is a trend towards high fuel injection pressures. Most OEMs worldwide have plans to introduce 350 bar fuel injection systems in the next few years, either across their entire portfolio or selected vehicles, and those decisions are taken for all production models, independent of the market. There are already investigations being made into 500 bar in the long term.

Raise the Bar

- 200 bar fuel pressure produces many large particulates

- 350 bar fuel pressure reduces the exhaust particulate number by 70%

- 500 bar fuel pressure further reduces particulate number by 50% versus 350 bar

However, diesel-like efficiency, that may come with diesel-like emissions and cost, if the wrong approach is taken,” says Mary Gustanski, Chief Technology officer of Delphi.

As far as pollutant emissions are concerned, the current focus is on particulate number reduction, but NOx could also come under intense scrutiny with the trend towards lean gasoline combustion. The introduction of Real Driving Emissions (RDE) and particulate number limits has hastened the development of gasoline particulate filters. Significant adoption is expected in Europe and China, but a minor uptake in North America.

Incidentally, adding a Gasoline Particulate Filter (GPF ) increases the exhaust back pressure, which compromises fuel efficiency. The 2018 Volkswagen up!, for example, has a 1.0-liter TSI engine with a coated GPF integrated in a 4-way catalyst and a 350-bar fuel injection system. This is a substantial added cost on an A-segment car where the margins are already thin, which shows the lengths that manufacturers are going to in order to be compliant.

“There is a strong possibility that we will see Selective Catalytic Reduction (SCR) and Lean NOX Traps (LNT) on gasoline for the first time,” says Gustanski.

The consensus within the research community is that lean combustion is the next natural step for gasoline fuel efficiency. There are a couple of approaches – namely stratified and homogenous – with varying degrees of efficiency benefits, and burdens on the after-treatment consequently.

Running lean will generate more NOx emissions and further after-treatment options will need to be considered, not least because performance of current 3-way catalysts is limited at lean conditions, but there is a strong possibility that we will see Selective Catalytic Reduction (SCR) and Lean NOX Traps (LNT) on gasoline engines for the first time.

Acronyms

- GPF = Gasoline Particulate Filter

- LNT = Lean NOX Trap

- RDE = Real Driving Emissions

- SCR = Selective Catalytic Reduction

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn.

He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe.

Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap.

AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks.

Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.

Death of the Diesel – High Gasoline Injection Pressures?

Click to Enlarge. Care must be taken because in the drive towards diesel-like efficiency, gasoline engines may come with diesel-like emissions and cost.

Diesel and gasoline share a common problem because there is a tricky trade-off to be made between emissions compliance and added cost. For gasoline, however, there is an additional dimension: CO₂ reduction. The main research on gasoline engines these days is, unsurprisingly, fuel efficiency, which directly correlates with CO2.

The gap with diesel is closing, but in more ways than just fuel efficiency. Expensive hardware, lean combustion, high pressure injection, compression-ignition – all quintessential characteristics of diesel engines – are now appearing on gasoline engines.

Efficient and hybridized gasoline should be the combustion-based alternative as diesel declines. Considering these added costs and complexities that have always been part of diesel, there is an unknown risk that the same pattern of reputational blight and penalties will occur on gasoline engines. This could/would accelerate the demise of the internal combustion engine while promoting electric vehicles.

There is a trend towards high fuel injection pressures. Most OEMs worldwide have plans to introduce 350 bar fuel injection systems in the next few years, either across their entire portfolio or selected vehicles, and those decisions are taken for all production models, independent of the market. There are already investigations being made into 500 bar in the long term.

Raise the Bar

However, diesel-like efficiency, that may come with diesel-like emissions and cost, if the wrong approach is taken,” says Mary Gustanski, Chief Technology officer of Delphi.

As far as pollutant emissions are concerned, the current focus is on particulate number reduction, but NOx could also come under intense scrutiny with the trend towards lean gasoline combustion. The introduction of Real Driving Emissions (RDE) and particulate number limits has hastened the development of gasoline particulate filters. Significant adoption is expected in Europe and China, but a minor uptake in North America.

Incidentally, adding a Gasoline Particulate Filter (GPF ) increases the exhaust back pressure, which compromises fuel efficiency. The 2018 Volkswagen up!, for example, has a 1.0-liter TSI engine with a coated GPF integrated in a 4-way catalyst and a 350-bar fuel injection system. This is a substantial added cost on an A-segment car where the margins are already thin, which shows the lengths that manufacturers are going to in order to be compliant.

“There is a strong possibility that we will see Selective Catalytic Reduction (SCR) and Lean NOX Traps (LNT) on gasoline for the first time,” says Gustanski.

The consensus within the research community is that lean combustion is the next natural step for gasoline fuel efficiency. There are a couple of approaches – namely stratified and homogenous – with varying degrees of efficiency benefits, and burdens on the after-treatment consequently.

Running lean will generate more NOx emissions and further after-treatment options will need to be considered, not least because performance of current 3-way catalysts is limited at lean conditions, but there is a strong possibility that we will see Selective Catalytic Reduction (SCR) and Lean NOX Traps (LNT) on gasoline engines for the first time.

Acronyms

About Ken Zino

Ken Zino, editor and publisher of AutoInformed, is a versatile auto industry participant with global experience spanning decades in print and broadcast journalism, as well as social media. He has automobile testing, marketing, public relations and communications experience. He is past president of The International Motor Press Assn, the Detroit Press Club, founding member and first President of the Automotive Press Assn. He is a member of APA, IMPA and the Midwest Automotive Press Assn. He also brings an historical perspective while citing their contemporary relevance of the work of legendary auto writers such as Ken Purdy, Jim Dunne or Jerry Flint, or writers such as Red Smith, Mark Twain, Thomas Jefferson – all to bring perspective to a chaotic automotive universe. Above all, decades after he first drove a car, Zino still revels in the sound of the exhaust as the throttle is blipped during a downshift and the driver’s rush that occurs when the entry, apex and exit points of a turn are smoothly and swiftly crossed. It’s the beginning of a perfect lap. AutoInformed has an editorial philosophy that loves transportation machines of all kinds while promoting critical thinking about the future use of cars and trucks. Zino builds AutoInformed from his background in automotive journalism starting at Hearst Publishing in New York City on Motor and MotorTech Magazines and car testing where he reviewed hundreds of vehicles in his decade-long stint as the Detroit Bureau Chief of Road & Track magazine. Zino has also worked in Europe, and Asia – now the largest automotive market in the world with China at its center.