General Motors is recalling 2020 Chevrolet Silverado 2500 and 3500 and GMC Sierra 2500 and 3500 pickup trucks. The hood-latch striker wires may not have been heat-treated properly by Motor City Stamping in Chesterfield MI. This can cause them to fracture allowing the hood to fly open. GM says it is not aware of any field claims alleging that a striker wire fractured. Continue reading

-

Recent Posts

- EPA Administrator and Trump Booster Zeldin Praises Himself

- Happy Clean New Year California Air Resources Board!

- Chicago Auto Show Shrinks

- Porsche – Happy Birthday Hans-Joachim Stuck

- Ford Recalls Mavericks, Escapes, Mach Es, Transits, Broncos

- Annals of Marketing – Kia and Times Square New Year Partyers

- December U.S. Vehicle Sales Forecast Down. Global Sales Up

- Mazda Axes Advance, Production and Design Modeling Studios

- Detroit Auto Show 2026 – Winners of HS Poster Contest

- Rising EV Sales Deepen Need for Charging Systems

- ACEA – EU November Car Sales Flat. Tesla Wilts

- Honda Aircraft Company Offers Performance Upgrade Package

- November 2025 UK Vehicle Production Plunges

- US New-Vehicle Sales Q4 Forecast Down in 2025. Year Up a Tad

- Toyota to Export U.S. Made Vehicles to Japan

Recent Comments

- Ken Zino on Ford Fuel Injector Leak Recall Now at ~694,000

- LAVERNE L OLIVER on Ford Fuel Injector Leak Recall Now at ~694,000

- Magna on its Share Repurchase Plan in reference to on Magna Posts Solid Q3 2025 Earnings Gain

- Daniel Ricciardo Global Ford Racing Ambassador on Ford Performance Rebranded as Ford Racing

- Gen 3 2026 Nissan Leaf Less than $30,000? | AutoInformed on Milestones – Nissan Begins Assembly of 2013 LEAF EV in Tennessee

Archives

Meta

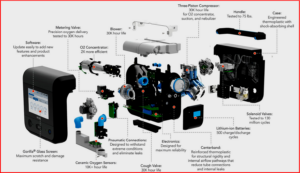

Ford Motor to Help 3M and GE Healthcare Expand Respirator and Ventilator Production

The arsenal of Democracy re-enlists…

3M and GE Healthcare are working with Ford Motor to expand production of respirators for healthcare workers, and ventilators for coronavirus patients. (see GM to Provide Logistical Support for Ventilator Production) Ford, in cooperation with the UAW, will assemble more than 100,000 plastic face shields per week at an idled Ford manufacturing site to help medical professionals, factory workers and store clerks. Ford also will also use its in-house 3D printing capacity to produce components for use in personal protective equipment.

Continue reading →