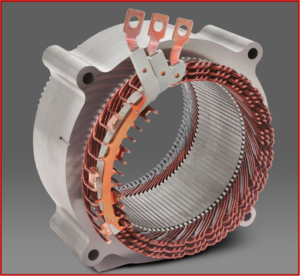

General Motors announced today plans to invest ~$154 million in its Western New York Lockport Components plant to renovate the facility and purchase and install new machinery and equipment used in the production of the stator module. Stators are key components in an electric motor. Electric motors will be used in a variety – currently 30 – of GM’s future Ultium Platform-based electric trucks and SUVs. Facility renovations begin immediately.

EV production – particularly final assembly is a huge concern for unions globally. “It’s pretty easy to build an EV since there are fewer components, and there are no EPA requirements or fluids,” Joe McCabe the CEO of AutoForecast Solutions told AutoInformed at a meeting of the International Motor Press Association earlier this week. Robots or non-skilled labor can do most of the work. (read AutoInformed on GM Cuts More Deals on Materials, Factories for EV Motors) Continue reading

Second Shift at GM Oshawa Assembly is Half Women

Inclusive culture, another long-standing resentment for fading white males?

Two months after the first Chevrolet Silverado rolled off the line at the reopened Oshawa Plant, second shift production has begun. In November, GM announced the hiring and training of 1,800 new jobs for two-shifts of production and the plant continues its launch acceleration. For the first time in the plant’s history, more than half of Oshawa’s new production hires are women. GM’s says this is consistent with its commitment to be the most inclusive company in the world.

Pickups trucks are GM’s largest and currently the most important market segment in North America. The Oshawa plant – once doomed only a couple of years ago as GM prepared to abandon it because of NAFTA and archaic attitudes toward labor, will help GM meet demand for trucks. Oshawa Assembly is now one of the most flexible and advanced of its kind in the industry, GM claims. Oshawa began shipping trucks to dealers in December 2021. Continue reading →